Pressure Safety valve or PSV Valve is the most important valve on a boiler used to relief excess pressure to atmosphere let’s see how psv valve is important, Let’s discuss about Pressure safety valve theory installation rules and PSV valve mechanism, Sv setting, testing and the types.

Purpose and safety PSV Valve

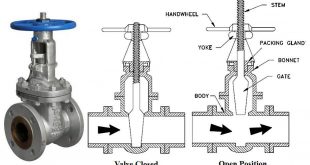

The maximum allowable working pressure (MAWP) for the most of the boilers is 10 bar. That is, the pressure of the steam in the boiler can not go above 10 bar. The purpose of the safety valve, then, is to prevent the pressure in the boiler from climbing above its MAWP. If the pressure were to rise above the MAWP, the safety valve would pop open and prevent any increase in pressure that might lead to a boiler explosion. The safety psv valve location should be the highest part of the steam side, in case of water tube at steam drum or directly to the top of the shell for fire tube boiler. There are no valves between the safety and the boiler.

Safety valves are designed to automatically pop open on pressure and stay open until there is a definite drop in pressure inside of the boiler. The pressure at which a PSV valve operates is known as blow down of safety valve & reseating pressure is called blow back, without chattering (opening and closing quickly). In most states, the only type of safety valve allowed on every steam boiler is the spring loaded type. You can calculate force acting to operate a safety valve Force= Pressure × Area. I recommend you to read Boiler codes to better under standing of safety valve theory.

Types of Safety Relief valve

- Spring loaded safety valve

- Pilot operated SRV

- Leaver type safety valve

- Dead weight safety valve

- High steam & low water SV

Installation

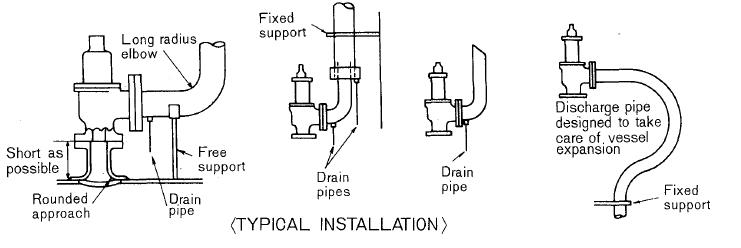

lt is the best practice to directly mount the safety valve in vertical position on a nozzle of the pressure vessel or a short connection which allows smooth flow of fluid. Where rounded or beveled approaches can not be provided ahead of the safety valve, it is recommended that one size larger riser or fitting be used. The pressure drop in the valve inlet piping should not exceed 3 % of the set pressure. Valves are sometimes badly damaged just as they go into service because of failure to clean the connections. It is essential that the boiler, pressure vessel, valve inlet, and all connections be cleaned thoroughly before the valve is mounted. For the gasket used for installation of a flange-type valve, an article whose gasket width is correct suitable for the flange bearing surface shall be used taking care not to allow displacement when bolt clamping takes place.

Any one of the Standards used for installing safety valve ASME Section-I, ISO-4126, BS-6759, 278, TRD.

ASME Guide about Safety relief valves

In Hydrostatic testing of a boiler flanged safety valves are usually blanked and Welded safety valves are closed with an internal plug called gagging. Gag plug should not be used in case of normal operation. SV should operate without chattering or any trouble.

Every steam, hot water boiler should have at least one PSV valve. Two are more Pressure safety valves are required for a boiler having heating surface above 500 f2, in case of electric boiler two psv valves are required above input of 1100kw.

The discharge capacity of a safety valve should equal to the generation capacity from and at 100 C of the boiler so that it can release all the steam.

Boiler pressure should not increase 6% of the set pressure of SV.

If two or more PSV are used, the max setting of PSV valve should not increase 3% of MAWP of the boiler.

The boiler having pressure above 15 PSI, Flanged or weld end connection should be used.

In case of failure of any part of a Safety valve, it should release steam without any hurdle.

Valve should be installed directly & in the vertical position with the boiler, no other valve is permitted between psv and boiler.

Reseat or blowback pressure should not increase from max 4% & min 2% (2psi) of set pressure. Forced flow steam generator that having no fix water line max reseats pressure should be 10% of set pressure.

The material of valve should be according to ASME B 16.34. Heat resistance alloy steel.

PSV Safety Valve Setting Example

If MAWP of a boiler is 200 Psi & we want to install 3 PSV valves two on the drum and one on the super heater, the setting will be as according to ASME codes.

One safety valve will be set at the pressure of 200 psi, second at 206 psi (3%) at the drum.

Super Heater safety valve pressure will be set at 185.4 (10% 206-20.6) (range 206×10/100)

Relieving capacity of drum safety valve should be 75% & Super heater 25% of boiler generation capacity.

Interval of periodic inspection

Safety valve must be subjected to an annual periodic inspection 1n accordance with the applicable laws Boiler & Pressure Vessel Code and other national standards. As for valves to which the rules of periodic inspection are not applicable, disassemble and overhaul them as follows

In principle, the interval of periodic inspection

(Disassembly and overhaul) is 1 to 2 years.

It should not exceed 4 years. [bws_pdfprint]

Boilersinfo Boiler and Mechanical Power Digital Library

Boilersinfo Boiler and Mechanical Power Digital Library