In almost any power, chemical, or mechanical system, heat must be transferred from one place to another or from one fluid to another. Heat exchangers are used to transfer heat from one fluid to another. A basic understanding of the mechanical components of a heat exchanger is important to understand how they function and operate.

Introduction to Heat Exchangers

A heat exchanger is a component that allows the transfer of heat from one fluid (liquid or gas) to another fluid. Reasons for heat transfer include the following:

1. To heat a cooler fluid by means of a hotter fluid.

2. To reduce the temperature of a hot fluid by means of cooler fluid.

3. To boil a liquid by means of a hotter fluid.

4. To condense a gaseous fluid by means of cooler fluid.

5. To boil a liquid while condensing a hotter gaseous fluid. Regardless of the function the heat exchanger fulfills, in order to transfer heat, the fluids involved must be at different temperatures and they must come into thermal contact. Heat can flow only from the hotter to the cooler fluid. In a heat exchanger, there is no direct contact between the two fluids. The heat is transferred from the hot fluid to the metal isolating the two fluids and then to the cooler fluid.

Classification and Types of Heat Exchangers

Heat exchangers are classified in many ways:

• According to the type of construction (shell and tube type or plate type);

• In terms of fluid flow through the heat exchanger (recuperator, regenerator or evaporative type).

- Classification of Heat Exchangers

- By Construction

- Shell and Tube Heat Exchangers

- Plate Heat Exchangers

- Finned Tube Heat Exchangers

- By Fluid Flow

- Parallel-Flow Heat Exchangers

- Counter-Flow Heat Exchangers

- Cross-Flow Heat Exchangers

- By Construction

- Types of Heat Exchangers

- Double-Pipe Heat Exchangers

- Spiral Heat Exchangers

- Air-Cooled Heat Exchangers

- Plate-Fin Heat Exchangers

Although heat exchangers come in every shape and size imaginable, the construction of most heat exchangers fall into one of two categories: tube and shell, or plate. As in all mechanical devices, each type has its advantages and disadvantages.

Types of heat exchangers Shell and tube type

The most basic and the most common type of heat exchanger construction is the shell and tube type. This type of heat exchanger consists of a set of tubes in a container called a shell. The fluid flowing inside the tubes is called the tube side fluid and the fluid flowing on the outside of the tubes is the shell side fluid. At the ends of the tubes, the tube side fluid is separated from the shell side fluid by the tube sheet(s). The tubes are rolled and press-fitted or welded into the tube sheet to provide a leak-tight seal. In systems where the two fluids are at vastly different pressures, the higher-pressure fluid is typically directed through the tubes and the lower pressure fluid is circulated on the shell side. This is due to the economy, because the heat exchanger tubes can be made to withstand higher pressures than the shell of the heat exchanger for a much lower cost. Animation of typical shell and tube-type heat exchanger is shown in the picture.

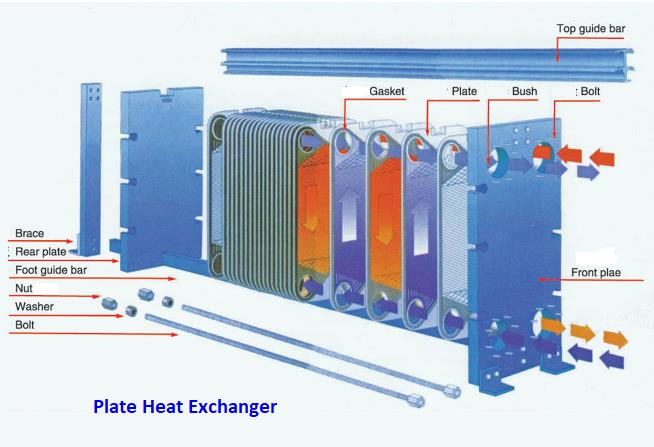

Plate Type Heat Exchangers

Plate type heat exchanger consists of plates instead of tubes to separate the hot and cold fluids. The hot and cold fluids alternate between each of the plates. Baffles direct the flow of fluid between plates. Because each of the plates has a very large surface area, the plates provide each of the fluids with an extremely large heat transfer area. Therefore a plate type heat exchanger, as compared to a similarly sized tube and shell heat exchanger, is capable of transferring much more heat. This is due to the larger area the plates provide over tubes. ( Heat Exchanger Design Handbook.)

Due to the high heat transfer efficiency of the plates, plate-type heat exchangers are usually very small when compared to tube and shell-type heat exchangers with the same heat transfer capacity. Plate-type heat exchangers are not widely used because of the inability to reliably seal the large gaskets between each of the plates. Because of this problem, plate-type heat exchangers have only been used in small, low-pressure applications such as on oil coolers for engines.

In conclusion, heat exchangers are indispensable devices that facilitate efficient heat transfer in various industries. Understanding their classification and types helps engineers and professionals make informed decisions when choosing the right heat exchanger for their applications.

FAQs

- What is the primary purpose of a heat exchanger?

The primary purpose of a heat exchanger is to transfer heat from one fluid to another while keeping them physically separated. Heat exchangers are used to either heat or cool a fluid depending on the specific application. They are widely employed in various industries to optimize temperature control, conserve energy, and facilitate efficient heat transfer processes.

- How do counter-flow and parallel-flow heat exchangers differ?

Counter-flow and parallel-flow heat exchangers differ in the direction of fluid flow within the exchanger:

- Counter-Flow Heat Exchangers: In a counter-flow heat exchanger, the hot and cold fluids flow in opposite directions. This design allows for the most efficient heat transfer because it maintains a high temperature difference between the two fluids throughout the process. As a result, counter-flow heat exchangers are highly efficient but can be more complex in construction.

- Parallel-Flow Heat Exchangers: In a parallel-flow heat exchanger, both the hot and cold fluids flow in the same direction. While this design is simpler, it is less efficient than counter-flow heat exchangers because the temperature difference between the fluids decreases as they move through the exchanger. Parallel-flow heat exchangers are often used in situations where a very high-temperature difference isn’t required.

- Can heat exchangers be used for both heating and cooling applications?

Yes, heat exchangers can be used for both heating and cooling applications. The direction of fluid flow and the temperature difference between the hot and cold fluids determine whether the heat exchanger provides heating or cooling. In heating applications, the heat exchanger transfers thermal energy from a hot fluid to a colder one, raising the temperature of the latter. In cooling applications, it transfers heat from a hot fluid to a colder one, thereby lowering the temperature of the former.

- What are some common maintenance practices for heat exchangers?

Common maintenance practices for heat exchangers include:

- Regular cleaning to remove fouling, scale, or deposits that can reduce efficiency.

- Inspection for leaks or damage to ensure safety and performance.

- Tube or plate replacement if corrosion or wear is detected.

- Checking and tightening connections to prevent leaks.

- Monitoring fluid flow rates and temperatures to maintain optimal performance.

- Implementing a regular maintenance schedule to prevent unexpected issues and extend the lifespan of the heat exchanger.

- Are plate heat exchangers more efficient than shell and tube heat exchangers?

The efficiency of plate heat exchangers compared to shell and tube heat exchangers depends on the specific application and requirements. Plate heat exchangers are generally more compact and offer high heat transfer efficiency due to their larger surface area, making them suitable for applications with limited space. Shell and tube heat exchangers, on the other hand, are robust and can handle high-pressure and high-temperature situations.

The choice between the two depends on factors like the available space, operating conditions, fluid properties, and maintenance considerations. Plate heat exchangers are often preferred when space and efficiency are critical, while shell and tube heat exchangers excel in demanding industrial settings. Each has its advantages and limitations, and the selection should be based on the specific needs of the application.

Boilersinfo Boiler and Mechanical Power Digital Library

Boilersinfo Boiler and Mechanical Power Digital Library