What is a water tube boiler?

Water tube boilers were developed for a variety of reasons, including the need for higher steam pressures, higher steam generation rate, superheated steam. these types of boilers have quicker response to load changes. We briefly discuss about Water tube boiler parts and functions.

In the water tube boiler, the water and steam flow inside the tubes and the hot gases flow over the outside surfaces. Where as in fire tube boilers hot gases from combustion travels through the tubes. flue gases produced from furnace where fuel is burnt.

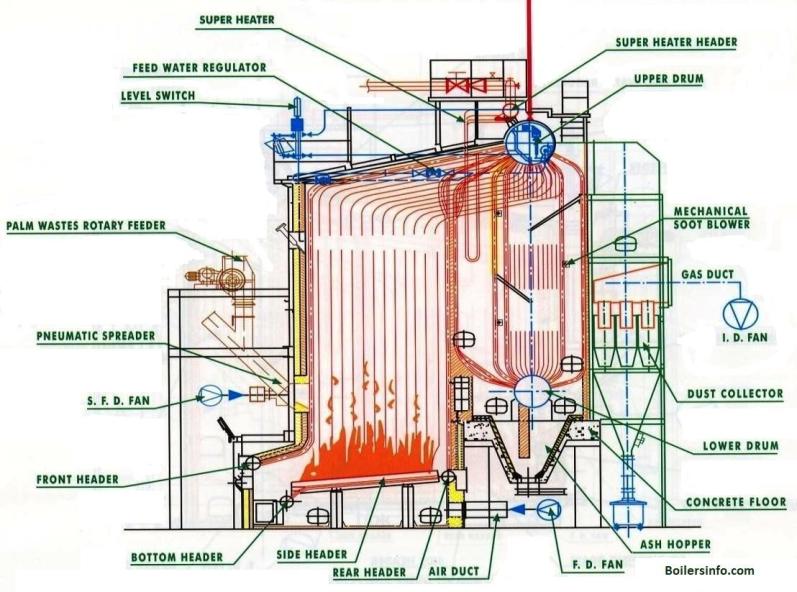

Water tube boiler design and working

In a typical Water tube boiler design as shown in the figure, it consists of two drums the steam drum and the water or mud drum. On this design straight tubes were rolled into mud drum, and the front headers were connected to the steam drum. The rear header was connected to a horizontal box header, which was also attached to the steam drum. The tubes were inclined to promote water circulation. There was also a spring loaded safety valve on top of the steam drum. In a water tube boiler fuel is fired into a water cooled furnace. Sheet metal and refractory enclosing the boiler called casing. At the end of the furnace, the flue gas turns into the convection section and travels towards the stack.

All boilers have a radiant and a conviction sections, tubes around the furnace are called generation or riser tubes about a half of steam is generated in this area rest of the steam is produced in the convection section. Water inside the tubes become hot and due to natural circulation steam is collected and separated in the steam drum. Pre heated (economiser) Feed water is continually feed in the steam drum with feed water pump.

These boilers were common in the paper making, sugar and other Industries which had big demands for electrical power and steam. Steam generated at high pressure and superheated would be fed to a turbine driving an alternator to generate electricity. Low-pressure steam leaving the turbine would then be used for the process.The smaller water tube boilers can be built at the manufacturers and delivered to site as one unit package water tube boiler. Most boilers, however, are built in sections and erected on the site.

Water tube boiler parts and their functions

There are many pressure parts and non pressure parts in a water tube boiler we only discuss main water tube boiler parts and function.

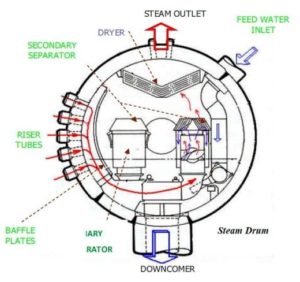

Steam drum

Steam drum is a collection vessel for steam & water. Here water & steam is separated. It has steam separators. Steam goes from top side to superheater & water goes from the bottom through down comer Mud drum, then to furnace bottom ring headers (bottom of furnace water wall).

It has two types of draining arrangement (a) CBD- continuous blow down used when Si02 or TDS is on the higher side. (b) Emergency blow down is used when drum level is high high. Boiler mountings and accessories like the safety valve, water level gauge and pressure gauge, feed water inlet connection are installed on this drum. Drum internals includes cyclone separators baffle plates rose pipe and the dry pipe. The main function of the steam drum is to provide water storage and space to separate steam from water.

Mud or Water Drum

Mud or water drum the lower drum is directly attached to upper steam drum with large no of straight tubes bundles called boiler bank tubes. Solids and mud can settle in this mud drum for removal through periodic blowdown. Some times desuperheater coil also installed in this drum to recover heat from superheated steam. Draining arrangement of this drum is through one or two boiler blowdown connections to control tds or to fully drain the boiler when out of service.

Water walls

Tubing arrangement around the furnace to extract heat from fuel to generate steam is called water wall circuit. These water walls can be arranged in line arrangement or stagger arrangement. Water walls get the heat from radiation and approximately absorb the 50% of the total heat produced in the furnace.

Super heater

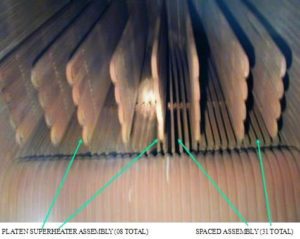

If the temperature of the steam is above its saturation temperature then it is called superheated steam. The super heater (heat exchanger) is used to increase the temperature of the steam. These are bundles of high strength tube which can bear temperature 600C Depending upon the material of tubes Mostly SA-213 is used. In most industrial water tube boilers the superheater is placed where flue gases make their turn from the radiant to the convection section of the boiler. There are three types of super heaters convection, radiant and conv-radient super heaters.

Economizer

Economizer (heat exchanger) is the boiler accessory used to recover the heat of flue gas that leaving the boiler by heating feed water. The efficiency of a boiler can be increased with an economizer. 60C rise in feed water temperature with the help of economizer can save up to 1% of fuel. Typically economiser is used before the air heater in flue gas path of athe boiler to increase the boiler efficiency.

Air Heater

Air supplied to a boiler for combustion is pre heated with the help of air heater by recovering the heat of waste flue gas that leaves the economizer. 20C rise in temperature of combustion air can save up to 1% of total fuel. Preheated air is also required for the operation of pulverized coal furnaces. Primary air is needed for drying coal in the pulverizer.

Air heaters are classified into two main types recuperative Air heaters and regenerative Air heaters.

Boiler Fans

For combustion of fuel in the boiler furnace air is drawn from the atmosphere and pushed through the ducts with forced draught fan to furnace where air reacts with fuel and become flue gas, the flue gas is then extracted from the furnace with the help of Induced draught fan. The fan used in large water tube boilers are FD fans, ID fans, Primary air fans, Secondary air fans and Gas recirculation fans.

Other main water tube boiler parts are burning equipment burners and furnace and gas cleaning devices like ESP Cyclone Separators and bag filters.

Boilersinfo Boiler and Mechanical Power Digital Library

Boilersinfo Boiler and Mechanical Power Digital Library