🛠️ Workshop Practice Series: Vertical Milling in the Home Workshop

The Workshop Practice Series is a classic collection for mechanical enthusiasts, and one of its most practical volumes is Vertical Milling in the Home Workshop by Arnold Throp. Aimed at home workshop owners and model engineers, this book serves as a complete guide for using a vertical milling machine effectively. It covers everything from machine setup to precision techniques, tool selection, and practical projects—all within the reach of a modest home workshop.

Introduction to Vertical Milling

Vertical milling machines differ from horizontal ones by the orientation of their spindle. In vertical mills, the spindle axis is vertical, allowing for operations like face milling, slotting, profiling, and drilling with excellent precision. They are incredibly versatile and suited for a wide range of materials—steel, aluminum, brass, and even plastics.

In the home workshop, the vertical mill becomes the heart of precision work. Whether you’re creating engine components, brackets, or custom tooling, the mill allows you to make exact parts with repeatability.

Selecting the Right Machine

For home use, choosing the right vertical mill involves balancing size, capability, and budget. The book emphasizes:

- Bench-top mills: Compact, suitable for small spaces, yet capable of high-precision work.

- Turret mills (like the Bridgeport-type): Larger, more versatile, but often impractical for limited space.

Key selection factors include:

- Spindle taper type (MT, R8, or ISO)

- Table size and travel

- Motor power and speed range

- Availability of digital readouts (DROs)

Arnold Throp focuses on practical machines that offer reliability and serviceability without overwhelming the home user.

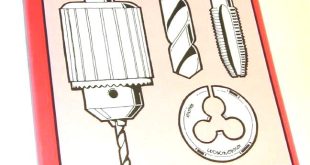

Tools, Cutters, and Workholding

Milling success depends heavily on using the right tooling. The book walks readers through:

- End mills, slot drills, face mills, and fly cutters—each with specific use cases.

- Workholding options: vices, clamps, T-slot fixtures, angle plates, and rotary tables.

- Tool materials: High-speed steel (HSS) vs. carbide tooling—important for different metals and workloads.

Safety and rigidity are emphasized. A secure setup ensures accuracy and prevents tool deflection or chatter.

Milling Operations Covered

Arnold Throp’s guidance includes a wide range of milling operations, such as:

- Facing and slab milling

- Slotting and pocketing

- Drilling and boring

- Angular milling with tilt/swivel heads

- Using the quill for fine depth control

Step-by-step processes are paired with practical examples, making it easier for beginners to build confidence while working.

Setting Up for Accuracy

An essential aspect of vertical milling is precision. The book explains how to:

- Square the milling head and vise for true, perpendicular cuts.

- Use a dial indicator or edge finder to zero on the workpiece.

- Employ DROs or leadscrew calibrations to maintain dimension control.

- Compensate for backlash and wear in older machines.

Simple adjustments and checks can make a big difference in finished parts, especially in small-scale engineering.

Maintenance and Safety

Throp emphasizes the need for regular machine maintenance:

- Keep slides clean and lubricated.

- Inspect belts, leadscrews, and gib strips.

- Use protective eyewear, chip guards, and wear snug clothing.

Home shops may not have the industrial safety controls of factories, so operator vigilance is critical.

Learning by Doing: Practical Projects

The book includes project examples to apply skills in real-world settings:

- Milling a parallel clamp

- Creating soft jaws for a milling vise

- Making accurate spacers and brackets

These projects reinforce the theory while producing tools that enhance future work.

Why It Matters

Vertical milling is a gateway to true precision machining. In the home workshop, it opens doors to custom fabrication, model engineering, maintenance, and prototype development. Arnold Throp’s approachable writing demystifies the process and empowers hobbyists to achieve professional results.

This volume in the Workshop Practice Series transforms the vertical mill from an intimidating piece of machinery into a dependable and creative tool.

Summary Table

| Topic | Key Takeaways |

|---|---|

| Machine Types | Bench-top, turret-style, R8/MT tapers |

| Tooling & Accessories | End mills, face mills, vices, angle plates, DROs |

| Operations | Facing, slotting, drilling, boring, angle milling |

| Accuracy Techniques | Squaring, backlash control, and indicator use |

| Maintenance & Safety | Lubrication, alignment checks, and operator protection |

| Project Examples | Soft jaws, brackets, and parallel clamps |

Conclusion & Book 📘

Vertical Milling in the Home Workshop is a gem for anyone looking to harness the power of milling in a small-space setup. With hands-on advice, clear illustrations, and a practical approach, Arnold Throp guides readers through the journey from novice to competent machinist. Whether you’re building small engines, model locomotives, or just need precise parts, this book belongs on your shelf—and your workbench.

Boilersinfo Boiler and Mechanical Power Digital Library

Boilersinfo Boiler and Mechanical Power Digital Library