What is boiler blowdown?

Boiler blowdown means a certain volume of water is blown off through the blowdown valve and is automatically replaced by feed water to maintain the desired level of total dissolved solids (TDS) in the boiler water.

Boiler feedwater usually contains a lot of dissolved and undissolved solids which is measured in total Dissolved Solids (TDS) contents in the boiler. These dissolved solids do not evaporate or escape during steam production and supply and settled at the bottom of the boiler shell or mud drum. This TDS causes serious trouble in the boiler ie increase in scaling, corrosion, and carryover localized overheating that may cause boiler tube failure or boiler explosion. Conductivity measurement is used for monitoring the overall TDS present in the boiler. A rise in conductivity indicates a rise in the “contamination” of the boiler water.

Types of Boiler Blowdown

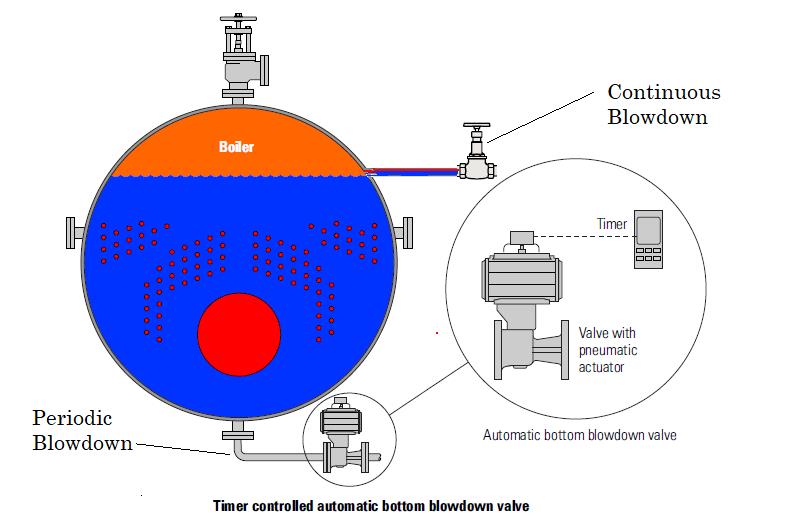

There are two types of boiler blowdown intermittent and continuous.

Intermittent or Periodic Blowdown

The intermittent blowdown is given by manually operating a valve fitted to the discharge pipe at the lowest point of the boiler shell to reduce parameters (IDS or conductivity, pH, Silica, and Phosphates concentration) within prescribed limits so that steam quality is not likely to be affected. In intermittent blowdown, a large diameter line is opened for a short period of time, the time is based on a thumb rule such as “once in a shift for 2 minutes. Also, a substantial amount of heat energy is lost with intermittent blowdown. 16% of blowdown means a total heat loss of 0.42%, making it imperative to maintain blowdown as per the optimum requirement.

Continuous Blowdown

There is a steady and constant removal of a small stream of concentrated boiler water through a continuous blowdown valve usually connected at the water level of the boiler, and replacement by the steady and constant inflow of feed water. This ensures constant TDS and steam purity at the given steam load. Once the blowdown valve is set for a given condition, there is no need for the regular operation of the valve. This type of blowdown is common in high-pressure boilers and a heat recovery system is also instead to recover the heat of blowdown water.

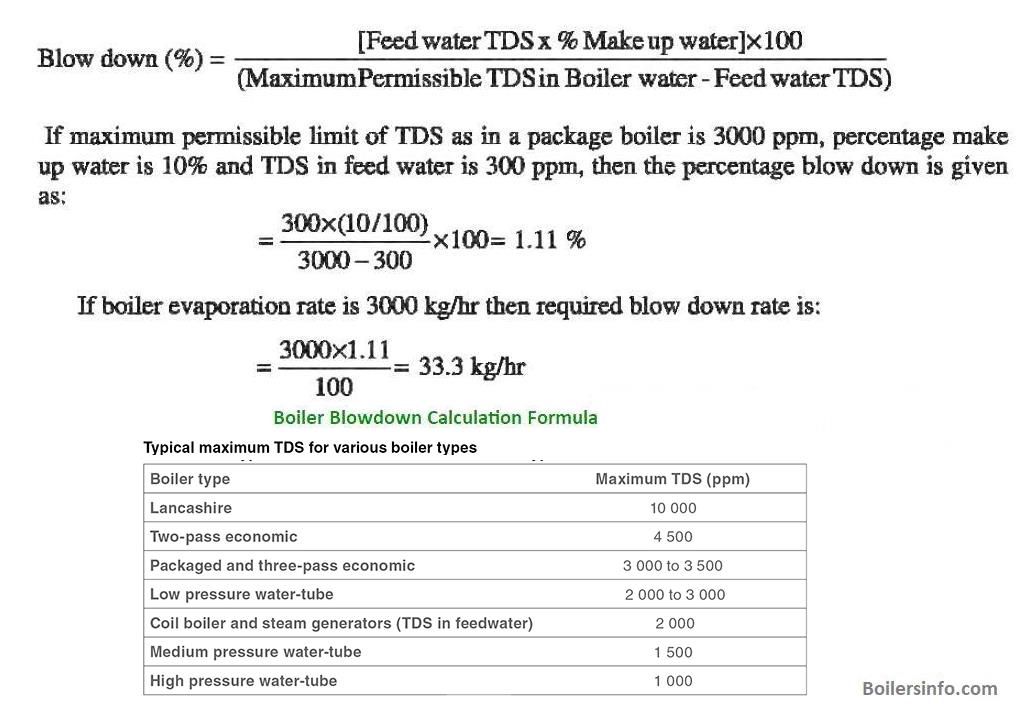

Boiler Blowdown Calculation Formula

The quantity of blowdown in the steam boiler required to control boiler water solids concentration is calculated by using the following formula:

Also, Read Boiler Water Treatment Basic

Boilersinfo Boiler and Mechanical Power Digital Library

Boilersinfo Boiler and Mechanical Power Digital Library