The purpose of an air compressor is to provide a continuous supply of pressurized air. An air compressor is a machine to compress the air and to raise its pressure. The air compressor sucks air from the atmosphere, compresses it and then delivers the same under high pressure to a storage vessel. From the storage vessel, it may be conveyed by the pipeline to a place where the supply of compressed air is required. Since the compression of air requires some work to be done on it, therefore a compressor must be driven by some prime mover.

Principle of operation

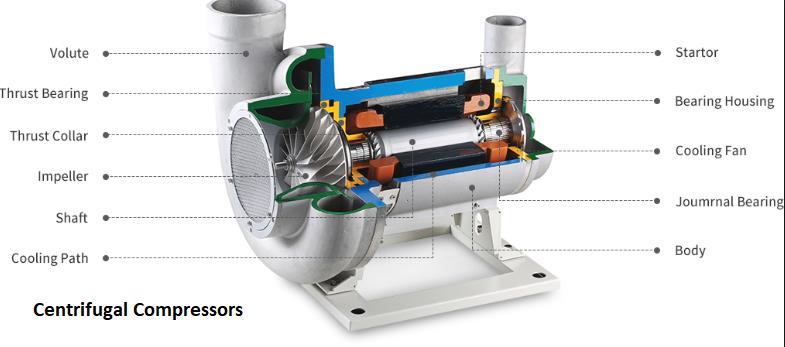

There is little difference between the principle of operation of compressors and pumps. One of the major differences is that for compressors we are dealing with a compressible fluid and it is that that leads us to the two basic classes, dynamic and positive displacement. Industrial uses of Compressed Air is used for many purposes such as for operating pneumatic drills, riveters, road drills, paint spraying, in starting and supercharging of internal combustion engines, in gas turbine plants, jet engines, and air motors, etc. It is also utilized in the operation of lifts, rams, pumps and a variety of other devices. Compressed air is also used for producing a blast of air in blast furnaces and Bessemer converters.

The principal applications of compressed air in Power Plants are as follows :

- High pressure instrument air

- Low pressure instrument air

- Breathing and cooling air

- Service air

Classification of Air Compressors

Air Compressors are classified in several ways such as:

• According to working (dynamic and positive displacement compressors);

• According to action (single acting and double acting compressors);

• According to number of stages (single stage or multi-stage compressors).

Dynamic Air Compressors

Dynamic compressors use rotating elements to accelerate air. By diffusing action, velocity is converted to static pressure. The total energy in a flowing air stream is constant. Entering an enlarged section, flow speed is reduced and some of the velocity energy turns into pressure energy. Thus static pressure is higher in the enlarged section. The dynamic class includes centrifugal and axial compressors.

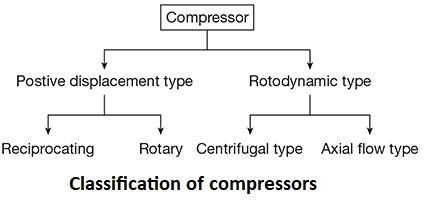

Centrifugal Compressors

The centrifugal compressor, originally built to handle only large volumes of low-pressure gas and air (maximum of 40 psig), has been developed to enable it to move large volumes of gas with discharge pressures up to 3,500 psig. The capacities of the centrifugal type compressors have improved over the years. It used to be that maximum pressure of 150 psi was all that could be achieved. However, pressures up to 550 psi are possible with 12,500 cfm. Lower pressure will allow a larger capacity and the maximum is about 150,000 cfm at 150 psi. However, centrifugal compressors are now most frequently used for medium volume and medium pressure air delivery. One advantage of a centrifugal pump is the smooth discharge of the compressed air. The centrifugal force utilized by the centrifugal compressor is the same force utilized by the centrifugal pump. A centrifugal compressor, in its simplest form, consists of a rotor (or impeller) to which a number of curved vanes are fitted symmetrically.

Axial Flow Compressors

Axial flow compressors accelerate air in a direction generally parallel to the shaft. Units resemble turbines; each pair of moving and stationary blade-rows forms a stage. Pressure rise per stage is relatively small. As the pressure rise is very small across a row of blades, many stages are used.

Rotary Air Compressors

The rotary compressor is adaptable to direct drive by induction motors or multi-cylinder gasoline or diesel engines. The units are compact, relatively inexpensive, and require a minimum of operating attention and maintenance. They occupy a fraction of the space and weight of a reciprocating machine of equivalent capacity. Rotary compressor units are classified into three general groups, slide vane-type, lobe-type, and liquid seal ring-type.

Reciprocating Compressors

The reciprocating air compressor is the most common design employed today. The reciprocating compressor normally consists of the following elements: a. The compressing element, consisting of air cylinders, heads and pistons, and air inlet and discharge valves.

Centrifugal and Axial Flow Compressors

These compressors present a more complex problem because of surging. This occurs when the flow falls below a certain value. Surging is when the flow becomes unstable because of secondary circulation created in the blade passages. This causes the flow as a whole to pulse and may damage the blading. The most common flow control arrangement used on centrifugal and axial flow compressors is the variable speed drive.

Boilersinfo Boiler and Mechanical Power Digital Library

Boilersinfo Boiler and Mechanical Power Digital Library