“ (FBC) Fluidized bed combustion is a combustion technology used to burn solid fuels in steam boilers.”

In Fluidized Bed Combustion Boiler technology When air or gas is passed through an inert bed of solid particles such as sand supported on a fine mesh or grid, the air initially will seek a path of least resistance and pass upward through the sand. With further increase in the velocity, the air bubbles through the bed and the particles attain a state of high turbulence. Under such conditions, the bed assumes the appearance of a fluid and exhibits the properties associated with a fluid and hence the name “Fluidized Bed combustion”.

MECHANISM OF FLUIDISED BED COMBUSTION

If the sand, in a fluidized state, is heated to the ignition temperature of the fuel and the fuel is injected continuously into the bed, the fuel will burn rapidly and the bed attains a uniform temperature due to effective mixing. This, in short is fluidized bed combustion.

While it is essential that temperature of bed should be at least equal to ignition temperature of fuel and it should never be allowed to approach ash fusion temperature (1050°C TO 1150°C) to avoid melting of ash. This is achieved by extracting heat from the bed by conductive and convective heat transfer through tubes immersed in the bed.

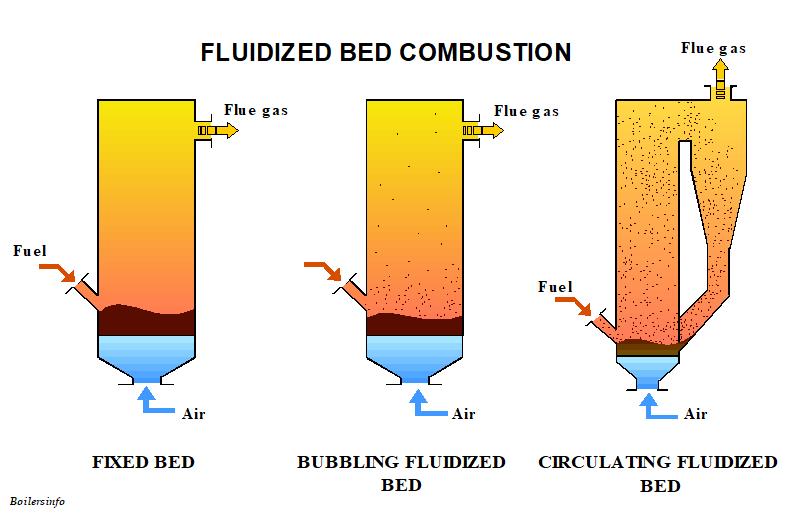

If velocity is too low, fluidization will not occur and if the gas velocity becomes too high, the particles will be entrained in the gas stream and lost. Hence to sustain stable operation of the bed, it must be ensured that gas velocity is maintained between minimum fluidization velocity and particle entrainment velocity.

Combustion temperature Excess air level and Superficial gas residence time are the principal factors that influence combustion efficiency of a FBC boiler. Combustion efficiency of Fluidized Bed Combustion (FBC) Boiler is 90% or greater.

TYPES OF Fluidized Bed Combustion FBC Boiler

- Fix Bed Boiler

- Bubbling fluidized bed (BFB) Boilers

- Circulating fluidized bed (CFBC) Boilers

These above fluidized-bed units mostly used to meet the demands of industries. They are all watertube boilers.

ADVANTAGES OF A FBC BOILER

Considerable reduction in boiler size is possible due to high heat transfer rate over a small heat transfer area immersed in the bed.

Low combustion temperature of the order of 750°C – 900°C facilities burning of coal with low ash fusion temperature, prevents NOx formation, reduces high temperature corrosion and erosion, and minimizes accumulation of harmful deposits due to low volatilization of alkali components.

High sulphur coals can be burnt efficiency without much generation of SOx by feeding limestone continuously with the fuel. Other benefits of FBC boiler are

- Fuel Flexibility

- High combustion efficiency than stocker PC boiler

- High combustion efficiency

- Low NOx emission

- Simpler fuel handling and feed system

- Small furnace cross-section area

- Good turndown ratio and load following capability

- High Availability

[bws_pdfprint]

Boilersinfo Boiler and Mechanical Power Digital Library

Boilersinfo Boiler and Mechanical Power Digital Library