Introduction to Potable Water Treatment Processes

Potable water treatment is a multi-step process designed to transform raw water into safe, clean drinking water. This process is governed by stringent water quality regulations established by organizations such as the World Health Organization (WHO), the U.S. Environmental Protection Agency (EPA), and the European Drinking Water Directive (DWD). These regulations specify acceptable limits for contaminants, including microorganisms, organic compounds, heavy metals, and emerging pollutants like microplastics. Treatment processes vary depending on the source water characteristics—whether surface water, groundwater, or desalinated water—each presenting unique challenges and requiring tailored solutions. Additionally, growing water demand due to population growth and climate change necessitates sustainable and efficient water treatment practices.

Table of Contents

TogglePhysical Treatment Processes

The treatment journey begins with physical processes such as coagulation, flocculation, and clarification. Coagulation involves adding chemicals like alum or ferric chloride to destabilize suspended particles, while flocculation promotes the aggregation of these particles into larger flocs through gentle mixing. These processes remove turbidity, color, and pathogens, preparing water for sedimentation or filtration. Clarification, often achieved through sedimentation basins or inclined plate settlers, separates solids from water under gravity. Alternatively, dissolved air flotation (DAF) uses microbubbles to float fine particulates and organic matter to the surface, making it particularly effective for algae-laden or oil-contaminated water. These steps improve water clarity and remove the bulk of suspended contaminants.

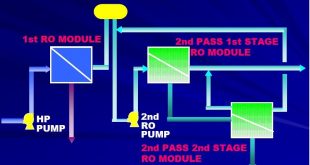

Filtration further enhances water quality by removing remaining particulates. Sand and granular activated carbon (GAC) filters are widely used for turbidity and organic matter removal, while advanced membrane technologies such as ultrafiltration (UF), microfiltration (MF), and reverse osmosis (RO) are employed for high-purity water production. Membrane systems are especially critical for desalination and demineralization. However, these systems require careful maintenance to address issues like fouling and scaling, often involving backwashing or chemical cleaning.

Chemical Treatment Processes

Chemical treatment processes play a crucial role in ensuring the microbiological and chemical safety of drinking water. Disinfection, achieved through methods such as chlorination, ozonation, or UV irradiation, eliminates pathogens and prevents waterborne diseases. Chlorine is commonly used due to its residual disinfectant properties, although excessive doses can form harmful byproducts. Organic and inorganic contaminants are addressed through advanced oxidation processes (AOPs), adsorption using activated carbon, and chemical precipitation. For example, nitrate and fluoride removal may involve ion exchange resins, while iron and manganese are typically removed through oxidation followed by filtration. These processes not only ensure compliance with regulatory standards but also improve water taste and appearance.

Sludge Treatment and Disposal

Water treatment generates sludge as a byproduct, containing suspended solids, coagulated particles, and other impurities. Proper sludge management is essential to minimize environmental impacts. Treatment begins with thickening to concentrate solids, followed by dewatering using centrifuges or belt presses. Stabilization methods, such as lime addition or anaerobic digestion, reduce pathogens and odors, making the sludge safer for disposal. Depending on its composition, treated sludge can be disposed of in landfills, used as a soil amendment, or even incinerated for energy recovery. Sustainable disposal practices are critical for reducing the ecological footprint of water treatment plants.

Boiler Water Treatment Basics

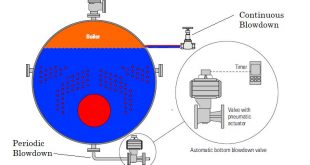

In industrial settings, boilers require high-quality water to prevent operational issues like scaling, corrosion, and fouling. This involves removing hardness through softening or demineralization, using oxygen scavengers like sodium sulfite to prevent rust, and maintaining alkaline pH levels to reduce metal dissolution. Effective boiler water treatment ensures operational efficiency, extends equipment lifespan, and minimizes energy consumption.

Conclusion

Potable water treatment combines physical, chemical, and advanced separation processes to produce safe and high-quality drinking water. It involves addressing a range of contaminants while adhering to regulatory standards to protect public health. Advances in membrane technologies, disinfection methods, and sludge management are crucial for meeting growing water demand sustainably.

Boilersinfo Boiler and Mechanical Power Digital Library

Boilersinfo Boiler and Mechanical Power Digital Library