Introduction of Nuclear Power Plant

In a nuclear power plant, nuclear fuel is used such as Uranium U235. The difference between a thermal power plant and nuclear power plant is fuel. Both use their fuel to convert water into steam in Boilers (Steam generators). This steam is used to run the steam turbine to produce electricity. The thermal power plant uses oil, coal, or gas while the nuclear plant uses nuclear fuel.

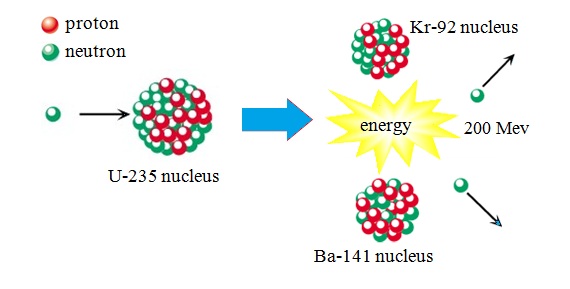

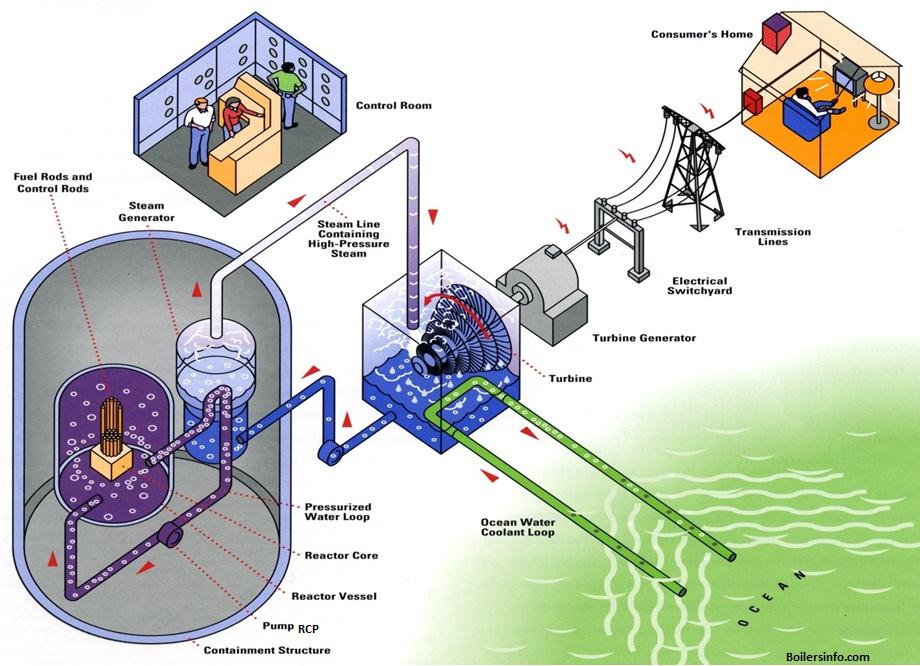

Nuclear Fuel energy is released by the nuclear Fission Chain reaction in the core of a reactor. 1 kg of Uranium U235 can produce as much energy equal to 3086 tons of coal or 136 m3 of fuel oil. A typical nuclear reaction is shown.

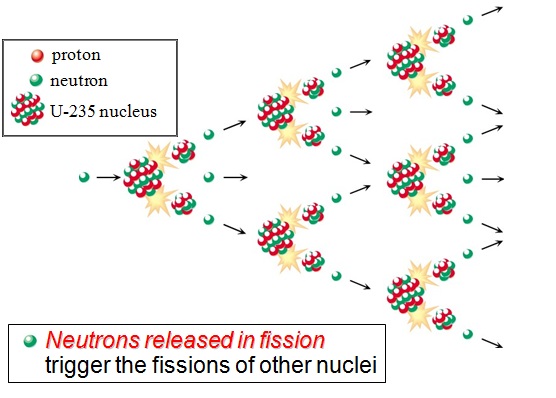

Nuclear Chain Reaction

When the nucleus of an atom of Uranium is split, the two or three neutrons released in this reaction these neutrons hit other atoms and split them in turn. More energy is released each time another atom splits. This phenomenon is called a chain reaction.The nuclear chain reaction can be controlled by control rods and by moderators.

Working of a Nuclear power plant

A nuclear power plant operates as a water-water heat exchanger. The process begins with the pumping of water, also known as coolant, at high pressure through the reactor core. The purpose of this process is to obtain heat energy from the chain reaction that takes place within the core. The water must be maintained at high pressure to prevent boiling.

Once the high-pressure radioactive water has been circulated through the reactor core, it is directed to the Steam Generator in a closed cycle loop. The Steam Generator functions to transfer the heat energy from the radioactive water to the Boiler feed water. This transfer occurs in a second closed cycle loop, which helps to keep the contaminated water separated from other equipment in the plant, such as the turbine and condenser.

After the heat transfer takes place in the Steam Generator, the heated Boiler feed water is converted into steam. This steam is then supplied to the conventional steam turbine generator. The steam causes the turbines to turn, which generates electricity.

As the steam passes through the turbine, it is then condensed to a liquid phase in the condenser. The condenser functions to cool the steam and return it as feedwater to the Steam Generator. This process completes the closed cycle loop.

Overall, the nuclear power plant operates as a water-water heat exchanger, using high-pressure radioactive water to generate heat energy from the chain reaction within the reactor core. The heat energy is then transferred to the Boiler feed water in a separate closed cycle loop, which produces steam. The steam is supplied to the turbine generator, generating electricity, and then condensed back into a liquid phase and returned as feedwater to the Steam Generator to complete the cycle.

There are thus two entirely separate closed circulating water loops; the primary (or reactor coolant) loop, which removes heat from the core, and the secondary (or steam generating) loop, which takes heat from the coolant and conveys it to the turbine. In the above animation, the containment structure is the primary loop.

Main Parts of a Nuclear Power Station

- Containment structure

- Reactor pressure vassal

- Steam generator

- Pressurizer

- Reactor Coolant pump RCP

- Feed water pump

- Steam turbine

- Control room

- Containment structure: This is a reinforced concrete structure that surrounds the reactor and other key components of the power station. It is designed to prevent the release of radioactive material in the event of an accident.

- Reactor pressure vessel: This is a thick-walled steel vessel that contains nuclear fuel and coolant. It is designed to withstand high pressure and temperature.

- Steam generator: This is a heat exchanger that transfers heat from the reactor coolant to the feedwater, which is then converted into steam to drive the turbine.

- Pressurizer: This is a vessel that is used to maintain the pressure of the coolant within the reactor.

- Reactor Coolant Pump (RCP): This is a high-pressure pump that circulates the coolant through the reactor and the steam generator.

- Feedwater Pump: This is a pump that supplies feedwater to the steam generator.

- Steam turbine: This is a machine that converts the energy of the steam into mechanical energy, which is then used to drive a generator to produce electricity.

- Control room: This is the nerve center of the power station, where operators monitor and control the operation of the plant. It is equipped with advanced control systems and safety mechanisms to ensure the safe and efficient operation of the power station.

- Emergency diesel generator: This is a backup generator that provides power to essential systems in the event of a power outage or other emergency.

- Coolant pumps: In addition to the RCP, there are usually several other pumps used to circulate coolant through the reactor and other systems.

- Condenser: This is a heat exchanger that cools the steam exiting the turbine and converts it back into liquid form, which can then be reused as feedwater in the steam generator.

- Cooling tower: This is a large structure used to cool the water that is circulated through the condenser. The tower works by evaporating some of the water, which removes heat and cools the remaining water.

- Electrical transformers: These are devices used to convert the voltage of the electricity produced by the generator to a level that is suitable for transmission on the electrical grid.

- Fuel storage pool: This is a pool or other storage facility used to store spent fuel rods that have been removed from the reactor.

- Radiation shielding: Various parts of the power station, including the reactor and steam generator, are lined with thick layers of lead, concrete, or other materials to protect workers and the environment from radiation.

These are just a few examples of the many parts and systems that make up a nuclear power station. Each power station is unique, and the specific components used can vary depending on the design of the plant and other factors.

Types of Nuclear Power Reactors

- Pressurized water reactor (PWR)

- Boiling water reactor (BWR)

- Heavy water reactor (HWR)

- Gas-cooled reactor (GCR)

- Liquid metal-cooled reactor (LMCR)

- Molten salt reactor (MSR)

- Pressurized water reactor (PWR): This is the most common type of nuclear reactor used in commercial power plants. It uses ordinary water as a coolant and a moderator, and a pressurized vessel to contain the reactor core.

- Boiling water reactor (BWR): This type of reactor also uses ordinary water as a coolant and a moderator, but it allows the water to boil directly in the reactor core to generate steam.

- Heavy water reactor (HWR): This type of reactor uses heavy water (deuterium oxide) as a moderator and coolant. Heavy water is used because it is a more efficient moderator than ordinary water, allowing the reactor to run on natural uranium instead of enriched uranium.

- Gas-cooled reactor (GCR): This type of reactor uses carbon dioxide or helium gas as a coolant instead of water. It is typically designed to run on enriched uranium fuel.

- Liquid metal-cooled reactor (LMCR): This type of reactor uses liquid metal, such as sodium or lead, as a coolant. Liquid metal-cooled reactors can operate at higher temperatures than water-cooled reactors, which makes them more efficient but also more complex to operate and maintain.

- Molten salt reactor (MSR): This type of reactor uses liquid fuel, typically a mixture of uranium and thorium dissolved in molten fluoride salts. The fuel is both the coolant and the moderator, and the reactor operates at high temperatures to allow the fuel to remain in a liquid state.

Difference Between PWR and BWR

In a Pressurized Water Reactor (PWR), ordinary water (H2O) is used as a coolant and a moderator. The water is kept at a high pressure to prevent it from boiling. The fuel is made of cylindrical pellets, which are filled in fuel rods and combined in assemblies. The fuel material typically used in PWRs is UO2, slightly enriched with 2 to 4%. The fuel pellets are stacked in Zircalloy tubes called cladding, with spaces left in some fuel assemblies for the insertion of control rods in the form of clusters.

The reactor core is surrounded by a steel core barrel, and the pressure vessel contains light water, which serves as a coolant, moderator, and reflector. Water collects heat from the fuel, giving it up into a steam generator, and is then pumped back into the reactor vessel. Modern PWRs have two to four independent steam generator loops in parallel.

Water enters the reactor pressure vessel (RPV) at a temperature of around 290°C, flows down around the outside of the core where it serves as a reflector, then passes through the core, where it removes the core’s heat, and finally exits the vessel at a temperature of about 325°C. The coolant then exhausts its heat to the water on the shell side of the steam generator, where it boils and produces steam.

In a boiling water reactor, the coolant and moderator is ordinary water (H2O), which is allowed to boil in the reactor core to produce steam. The fuel is shaped as cylindrical pellets, filled up in fuel rods, and combined in assemblies. Fuel material is usually UO2 slightly enriched 2 to 5% is used in most BWR power plants. Fuel pellets are stacked in Zircalloy tubes called cladding. Spaces are left in some fuel assemblies for the insertion of control rods. Control rods are in the form of clusters. The reactor core is surrounded by a steel core shroud. Water is heated in the reactor core and is allowed to boil, producing steam. The steam directly drives the turbine generator and is then condensed back into liquid water in a condenser and returned to the reactor as feedwater. The reactor pressure vessel contains the fuel, moderator, and coolant, with the steam generated directly in the core. The steam is separated from the water in the upper part of the vessel and is used to power the turbine. The remaining water is then returned to the core.

Safety in Nuclear power plant

Safety is of paramount importance in nuclear power plants. Nuclear reactions in a power plant can produce large amounts of heat and radiation that must be contained and controlled to prevent accidents and protect workers and the public. Nuclear power plants are designed and operated with multiple layers of safety features to prevent accidents and minimize the consequences of any accidents that might occur.

Boilersinfo Boiler and Mechanical Power Digital Library

Boilersinfo Boiler and Mechanical Power Digital Library