Coal-Fired Power Generation: Fundamentals, Systems, and the Future

Coal-fired power generation has historically been the backbone of electricity supply for many nations. Despite increasing interest in renewables, coal remains an integral part of the global energy mix, especially in developing countries. Understanding the complete coal power cycle—from resource occurrence to environmental implications—is essential for optimizing existing infrastructure and evaluating the future of coal in a transitioning energy world.

Occurrence and Resources

Coal is a sedimentary rock formed from ancient plant material compressed and heated over millions of years. It occurs in large reserves worldwide, with significant deposits in the United States, China, India, Australia, and Russia. The abundance of coal has historically made it a reliable and economically attractive energy source.

Classification

Coal is classified based on carbon content, energy density, and moisture levels. The four main types are:

- Anthracite – Highest carbon content and energy value

- Bituminous – Commonly used in power generation

- Sub-bituminous – Lower energy content, higher moisture

- Lignite – Least mature, high moisture, and lower calorific value

Recovery, Preparation, and Transportation

Coal is extracted through surface (open-pit) or underground mining. After recovery, it undergoes preparation processes such as crushing, screening, and washing to remove impurities. Transportation—via rail, barge, or conveyor—is a key logistical component, especially for inland power plants far from coal mines.

Storage

Once at the plant, coal is stored in open yards or silos. Proper storage is vital to prevent spontaneous combustion and ensure consistent feedstock quality. Dust suppression and runoff control systems are essential to minimize environmental and safety hazards.

Steam Plant Operation

In a typical coal-fired plant, pulverized coal is burned in a boiler to generate high-pressure steam. This steam drives a turbine connected to a generator, converting thermal energy into electricity. Efficient steam cycle design—including reheating, feedwater heating, and high-pressure operation—significantly impacts overall plant efficiency.

General Properties

Coal’s utility as a fuel depends on its:

- Heating Value – Measured in BTU or MJ/kg

- Volatile Matter – Influences ignition and flame stability

- Ash Content – Affects slagging and fouling in the boiler

- Moisture Content – Reduces efficiency and increases emissions

Physical, Mechanical, and Thermal Properties

Coal’s grindability, friability, and swelling index influence handling and pulverization systems. Thermal properties like calorific value and ash fusion temperature directly impact combustion performance and slag formation.

Combustion and Combustion Systems

Coal combustion occurs in three main systems:

- Pulverized Coal (PC) – Most common, provides rapid and complete combustion

- Fluidized Bed Combustion (FBC) – Allows lower temperature combustion, reducing NOₓ formation

- Stoker Boilers – Used for small-scale or low-quality coal

Combustion efficiency depends on air-fuel ratios, residence time, and temperature control within the furnace.

Gasification

Coal gasification converts coal into syngas (CO and H₂), which can be burned in a gas turbine or used in chemical synthesis. Gasification provides cleaner combustion and is a gateway to Integrated Gasification Combined Cycle (IGCC) plants.

Gasification Systems

Modern gasification technologies include:

- Fixed Bed (Lurgi)

- Fluidized Bed

- Entrained Flow (GE, Shell)

Each system varies in temperature, pressure, and feedstock flexibility, impacting syngas composition and downstream cleanup needs.

Electric Power Generation

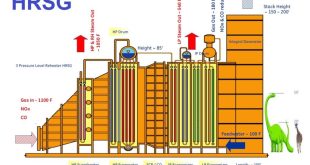

In conventional setups, steam turbines are the primary method of converting heat into electricity. IGCC plants, however, use both gas and steam turbines in a combined cycle, significantly improving efficiency and reducing emissions.

Gas Cleaning

Before syngas is used for combustion or chemical production, it must be cleaned of particulates, sulfur compounds (e.g., H₂S), and trace metals. Technologies include cyclones, scrubbers, fabric filters, and selective catalytic reduction (SCR) systems.

Environmental Aspects of Power Generation

Coal plants face increasing scrutiny due to emissions of CO₂, SO₂, NOₓ, mercury, and particulates. Environmental compliance involves:

- Flue Gas Desulfurization (FGD)

- Electrostatic Precipitators (ESP)

- Low-NOₓ Burners

- Ash Handling and Wastewater Treatment

Carbon capture, utilization, and storage (CCUS) is emerging as a critical technology for reducing greenhouse gas emissions from coal power.

Clean Coal Technologies

To make coal power more sustainable, clean coal technologies focus on:

- High-efficiency, low-emission (HELE) plants

- Supercritical and ultra-supercritical boilers

- IGCC and oxy-fuel combustion

- Pre-combustion and post-combustion CO₂ capture

Coal and Energy Security

For many nations, coal provides a foundation for energy independence and grid reliability. Unlike natural gas or renewables, coal is easily stockpiled, ensuring long-term supply during geopolitical or weather disruptions.

Boilersinfo Boiler and Mechanical Power Digital Library

Boilersinfo Boiler and Mechanical Power Digital Library