Gas or Steam Turbines are essential equipment in various industries, including power generation, oil and gas, and manufacturing. To ensure their efficient and reliable operation, turbine supervisory instrumentation (TSI) plays a vital role. TSI encompasses a range of monitoring and measurement tools that provide critical data about the turbine’s performance and condition. In this article, we will explore the different types of TSI and their significance in maintaining turbine health.

What is Turbine Supervisory Instrumentation?

Turbine supervisory instrumentation refers to a set of sensors, devices, and software that monitor and control various parameters of a turbine system. It continuously collects and analyzes data related to temperature, pressure, vibration, speed, and other crucial indicators to ensure the turbine operates within safe limits and optimal performance.

Importance of Turbine Supervisory Instrumentation

Turbines are complex machines used in power generation, and their efficient operation is essential for meeting energy demands. Turbine supervisory instrumentation plays a crucial role in achieving this efficiency. Here’s why it is so important:

1. Enhancing Performance

By providing real-time data and insights, turbine supervisory instrumentation helps optimize turbine performance. Operators can monitor critical parameters and make informed adjustments to improve efficiency, reduce energy losses, and maximize power output.

2. Preventing Failures

Early detection of potential issues is vital to prevent costly breakdowns and minimize downtime. Turbine supervisory instrumentation enables operators to monitor vibration levels, temperature variations, and other warning signs, allowing them to take proactive measures and avoid catastrophic failures.

3. Safety and Protection

Turbine systems operate under high pressures and temperatures, posing risks to both equipment and personnel. Supervisory instrumentation provides operators with crucial safety information, ensuring that the turbine operates within safe limits and mitigating potential hazards.

4. Data-Driven Decision Making

Turbine supervisory instrumentation generates a wealth of data that can be analyzed to identify trends, patterns, and areas for improvement. This data-driven approach enables operators to make informed decisions regarding maintenance schedules, operational adjustments, and long-term performance enhancements.

Key Components of Turbine Supervisory Instrumentation

Turbine supervisory instrumentation comprises several essential components that work together to monitor and control turbine systems effectively. These include:

1. Sensors

Sensors are the primary data collection devices in turbine supervisory instrumentation. They measure parameters such as temperature, pressure, flow rate, vibration, and rotational speed, providing real-time data for analysis.

2. Data Acquisition Systems

Data acquisition systems capture and process data from sensors. They convert analog signals into digital format, allowing for further analysis and visualization.

3. Control Systems

Control systems receive data from the data acquisition systems and implement control strategies to optimize turbine performance. They regulate variables such as fuel flow, steam pressure, and valve positions to maintain efficient and safe operation.

4. Human-Machine Interface (HMI)

HMIs provide a graphical representation of the turbine system, displaying real-time data, alarms, and control options. Operators can interact with the HMI to monitor the turbine’s performance, acknowledge alarms, and make adjustments if necessary.

Benefits of Turbine Supervisory Instrumentation

The utilization of turbine supervisory instrumentation offers numerous benefits to power generation facilities. Some notable advantages include:

- Improved Efficiency: By monitoring key parameters, turbine supervisory instrumentation helps identify energy losses and inefficiencies, enabling operators to make targeted improvements and optimize overall efficiency.

- Enhanced Reliability: Early detection of potential failures and timely maintenance based on instrumentation data significantly improve the reliability of turbine systems, reducing unexpected downtime.

- Cost Reduction: Optimized performance and decreased downtime result in cost savings for power generation facilities. By preventing failures and maximizing efficiency, turbine supervisory instrumentation helps minimize repair and operational expenses.

- Remote Monitoring: With advanced supervisory instrumentation systems, operators can monitor turbine performance remotely. This capability allows for prompt response to alarms or issues, reducing the need for on-site troubleshooting.

Types of Turbine Supervisory Instrumentation

Turbine supervisory instrumentation encompasses various types of sensors and systems, including:

1. Bearing Vibration

Bearing vibration is a key parameter monitored in turbines. It indicates the level of vibration experienced by the bearings supporting the rotating components. Excessive vibration can lead to premature bearing wear, reduced efficiency, and potential failure. TSI systems measure bearing vibration on a scale of 1 to 10, where 1 represents low vibration and 10 represents high vibration. By continuously monitoring bearing vibration, operators can identify abnormalities and take preventive measures to avoid costly downtime and damage.

2. Zero Speed

Zero-speed monitoring is crucial for safe turbine operations. This TSI feature ensures that the turbine or specific components come to a complete stop before maintenance or startup procedures are performed. By detecting zero speed accurately, operators can prevent accidental start-ups, which can be hazardous and result in equipment damage or personal injury.

3. Digital Speed

Digital speed instrumentation provides real-time monitoring of the turbine’s rotational speed. Measured in revolutions per minute (rpm), this TSI feature allows operators to track the speed within a range of 0 to 3000 rpm. Maintaining the turbine speed within the desired operating range is vital for ensuring optimal performance and avoiding excessive stress on the turbine’s components.

4. Case Expansion

Turbine casings are subject to expansion or contraction due to temperature changes during operation. Case expansion TSI instruments monitor the expansion of the turbine casing, helping operators identify potential issues such as excessive stresses, misalignments, or leaks. By detecting abnormal case expansion, necessary corrective actions can be taken to prevent further damage and maintain the integrity of the turbine.

5. Rotor Eccentricity

Rotor eccentricity refers to the deviation or displacement of the rotor’s center of rotation from its true geometric center. TSI systems measure rotor eccentricity to identify any misalignment or imbalance in the rotating components. Excessive eccentricity can lead to increased vibration, reduced efficiency, and even mechanical failure. By continuously monitoring rotor eccentricity, operators can detect early signs of misalignment and take corrective measures to ensure smooth turbine operation.

6. Rotor Position

Accurate positioning of the rotor is crucial for efficient turbine operation. TSI instruments monitor the rotor position relative to its intended location. Deviations from the desired position can impact the turbine’s performance and increase stress on the components. By monitoring rotor position, operators can detect misalignments, mechanical issues, or any undesired movement. This information enables timely adjustments or repairs to maintain optimal turbine performance.

7. Differential Expansion

Differential expansion refers to the difference in expansion or elongation between two different parts or components of the turbine. TSI systems measure and monitor differential expansion to ensure balanced expansion across the turbine. Significant differential expansion can result in mechanical binding, misalignment, or excessive stress, leading to equipment failure. By monitoring and controlling differential expansion, operators can prevent these issues and extend the turbine’s lifespan.

Installation and Maintenance of Turbine Supervisory Instrumentation

The proper installation and regular maintenance of turbine supervisory instrumentation are crucial for its effective operation. Qualified technicians and engineers should handle the installation process, ensuring accurate sensor placement, correct wiring, and integration with control systems.

Ongoing maintenance includes periodic calibration, sensor replacements as needed, and software updates to keep the system up to date. Regular inspections and data analysis help identify potential issues early on, enabling proactive maintenance and optimal turbine performance.

Challenges and Future Trends

While turbine supervisory instrumentation offers significant benefits, there are challenges and future trends to consider:

- Data Management: With the increasing amount of data generated by supervisory instrumentation, efficient data management and analysis become vital. Advanced analytics tools and machine learning algorithms will play a crucial role in extracting valuable insights from this data.

- Cybersecurity: As turbine systems become more interconnected and data is transmitted over networks, ensuring robust cybersecurity measures becomes imperative. Protecting against cyber threats and unauthorized access is essential to maintain the integrity and reliability of turbine supervisory instrumentation.

Conclusion

Turbine supervisory instrumentation plays a pivotal role in optimizing the performance and reliability of turbine systems. By monitoring critical parameters, detecting potential issues, and providing real-time data, this instrumentation enables operators to make informed decisions, prevent failures, and enhance overall efficiency. The future of turbine supervisory instrumentation lies in advanced data analytics, cybersecurity, and further integration with emerging technologies. Embracing these advancements will lead to even more efficient and resilient turbine systems in the years to come.

FAQs

1. How does turbine supervisory instrumentation improve turbine efficiency? Turbine supervisory instrumentation monitors key parameters, allowing operators to identify energy losses and make targeted improvements to enhance overall efficiency.

2. Can turbine supervisory instrumentation prevent catastrophic failures? Yes, by detecting warning signs and providing real-time data, turbine supervisory instrumentation helps operators take proactive measures to prevent catastrophic failures.

3. Is turbine supervisory instrumentation only used in power generation? While power generation is a primary application, turbine supervisory instrumentation is also used in other industries, including oil and gas, chemical processing, and manufacturing.

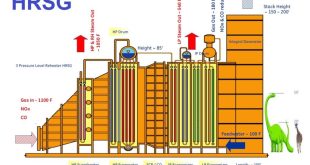

Boilersinfo Boiler and Mechanical Power Digital Library

Boilersinfo Boiler and Mechanical Power Digital Library