Advanced Power Plant Materials, Design, and Technology

The energy landscape is evolving rapidly, with advancements in power plant materials, designs, and technologies helping to meet increasing energy demands, improve efficiency, and minimize environmental impacts. The implementation of cutting-edge technologies in thermal and gas-based power generation systems has opened up new possibilities for more efficient, environmentally-friendly, and cost-effective power plants. This article explores the latest developments in power plant materials and technologies, focusing on gas turbine systems, combined-cycle power plants, and sustainable energy sources like biomass and hydrogen.

Advanced Gas Turbine Materials, Design, and Technology

Gas turbines are at the heart of modern power generation, particularly in combined-cycle plants where they work alongside steam turbines for optimal efficiency. As the demand for higher efficiency and lower emissions increases, advancements in gas turbine technology focus on enhancing materials, designs, and operational processes. Key areas of development include:

- Advanced Alloys: High-temperature materials such as single crystal superalloys are essential for improving turbine blade efficiency and longevity. These materials withstand extreme conditions, allowing turbines to operate at higher temperatures and pressures.

- Cooling Technologies: Advanced cooling systems, including film cooling and transpiration cooling, are crucial to protecting turbine blades from high temperatures, enabling them to operate more efficiently and with lower wear and tear.

- Additive Manufacturing: The use of 3D printing for turbine components offers improved material precision, reduced waste, and faster production times, allowing for more customized and durable parts.

Gas-Fired Combined-Cycle Power Plant Design and Technology

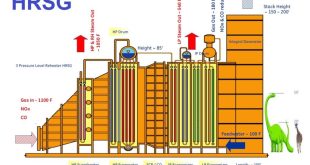

Gas-fired combined-cycle power plants (CCPPs) combine both gas and steam turbines to increase the efficiency of electricity generation. By using waste heat from the gas turbine to generate steam that drives a steam turbine, CCPPs achieve efficiency levels exceeding 60%, compared to conventional steam-only plants.

- Efficiency Improvements: Modern CCPPs incorporate advanced materials and technologies such as high-efficiency gas turbines and heat recovery steam generators (HRSGs), which help maximize the energy extracted from the fuel.

- Hybrid Systems: The integration of renewable energy sources (e.g., solar or wind) with combined-cycle systems is an emerging trend, enabling power plants to operate more flexibly and sustainably while maintaining high efficiency.

- Emissions Control: Enhanced combustion systems and advanced emission control technologies help to significantly reduce NOx, CO2, and other pollutants, improving the plant’s environmental performance.

Integrated Gasification Combined Cycle (IGCC) Power Plant Design and Technology

IGCC technology combines the gasification of coal or biomass with combined-cycle power generation. In IGCC plants, solid fuel is converted into syngas (a mixture of hydrogen, carbon monoxide, and carbon dioxide), which is then used in gas turbines to generate electricity.

- Fuel Flexibility: IGCC plants can use a variety of fuels, including low-rank coal, petroleum coke, and biomass, offering greater fuel flexibility than traditional coal-fired power plants.

- Carbon Capture: IGCC offers significant potential for integrating carbon capture and storage (CCS) technologies, enabling the reduction of CO2 emissions by capturing and storing them underground.

- Efficiency and Sustainability: IGCC plants have the potential for greater efficiency than conventional coal-fired power plants, with integrated systems for heat recovery, gas cleaning, and CO2 capture.

Improving Thermal Cycle Efficiency in Advanced Power Plants

Thermal efficiency is a critical factor in power plant performance. Modern technologies are focused on improving thermal cycle efficiency to extract more energy from the fuel, thereby reducing operating costs and environmental impact.

- Supercritical and Ultra-supercritical Steam: By operating at higher temperatures and pressures than traditional steam cycles, supercritical and ultra-supercritical steam cycles enable greater efficiency in electricity generation.

- Advanced Turbine and Generator Designs: Turbines designed to operate at higher temperatures, combined with advanced materials, increase the efficiency of thermal cycles while reducing fuel consumption and emissions.

- Waste Heat Recovery: Advanced heat recovery systems allow plants to capture and reuse waste heat, improving overall efficiency and lowering energy consumption.

Water and Steam Chemistry and Materials Performance

The performance of materials in contact with water and steam is critical to the reliability and efficiency of power plants. Advanced chemistry and material technologies are being implemented to combat issues like corrosion, scaling, and fouling that can degrade plant efficiency.

- Water Treatment Systems: Advanced water chemistry management ensures the proper treatment of boiler feed water to prevent scaling, corrosion, and fouling. This contributes to the longevity and efficiency of power plant components.

- Boiler Materials: The development of corrosion-resistant materials, such as high-alloy steels, improves the durability of boiler components in aggressive steam conditions.

- Monitoring and Control: Advanced online monitoring systems allow for real-time analysis of water quality, enabling operators to adjust treatment strategies and ensure optimal performance.

Advanced Hydrogen Gas Separation Membrane

Hydrogen is emerging as a key fuel for future power plants, especially in combination with renewable energy sources. Advanced hydrogen gas separation membranes are crucial in efficiently separating hydrogen from other gases, enabling its use as a clean fuel in power generation.

- Membrane Technology: Advanced polymer and ceramic membranes are being developed for selective hydrogen separation, offering high efficiency, low energy consumption, and cost-effectiveness.

- Applications in IGCC and Gas Turbines: Hydrogen separation can be integrated into IGCC and gas turbine systems to enhance fuel flexibility and reduce greenhouse gas emissions.

Advanced Flue Gas Cleaning Systems for SOx and NOx

As environmental regulations become stricter, power plants must adopt advanced flue gas cleaning systems to reduce emissions of sulfur oxides (SOx) and nitrogen oxides (NOx).

- Selective Catalytic Reduction (SCR): SCR systems use catalysts to convert NOx into nitrogen and water, significantly reducing NOx emissions.

- Flue Gas Desulfurization (FGD): FGD systems use chemical reactions to remove sulfur from flue gases, reducing SOx emissions and preventing acid rain.

- Particulate Removal: Advanced filtration systems such as electrostatic precipitators (ESPs) and fabric filters are employed to capture particulate matter and other pollutants.

Combined Cycle Gas and Steam Turbine Power Plants

Combined cycle plants utilize both gas and steam turbines for efficient power generation. The waste heat from the gas turbine is used to produce steam, which drives a steam turbine, leading to greater energy extraction from the same amount of fuel.

- High Efficiency: The combination of gas and steam turbines improves thermal efficiency, reducing fuel consumption and emissions.

- Flexible Operation: Combined cycle plants can quickly respond to changes in demand, making them ideal for balancing renewable energy sources like wind and solar.

Advanced Monitoring and Process Control Technology for Coal-Fired Power Plants

The operation of coal-fired power plants can be optimized using advanced monitoring and process control systems. These systems collect data from sensors placed throughout the plant, allowing for better control of operations, early detection of issues, and improved efficiency.

- Real-time Data Collection: Sensors monitor variables such as pressure, temperature, and flow rates, providing operators with up-to-date information on plant performance.

- Predictive Maintenance: Advanced monitoring systems can predict equipment failures before they occur, reducing downtime and maintenance costs.

Low-Rank Coal Properties, Upgrading, and Utilization

Low-rank coals, such as lignite, present unique challenges due to their high moisture content and lower energy density. However, advanced technologies are enabling the efficient upgrading and utilization of these fuels.

- Coal Upgrading: Techniques like drying and briquetting improve the energy content of low-rank coal, making it more suitable for power generation.

- Gasification: Low-rank coal can be gasified to produce syngas, which can then be used in combined-cycle power plants for cleaner energy production.

Biomass Resources, Fuel Preparation, and Utilization

Biomass is increasingly being used as a renewable energy source in power generation. Advances in fuel preparation and combustion technologies are making biomass a viable alternative to fossil fuels.

- Biomass Preprocessing: Biomass can be preprocessed to improve its energy density and combustion efficiency.

- Co-Firing: Biomass can be co-fired with coal in existing power plants, reducing carbon emissions and providing a sustainable energy source.

Power Plant Engineering and Syngas and Hydrogen Production Technologies

Advanced technologies in syngas and hydrogen production are central to the future of power generation. The integration of gasification, hydrogen separation, and renewable energy technologies opens up new possibilities for cleaner, more efficient power plants.

- Syngas Production: Gasification of biomass and coal produces syngas, which can be used for power generation, chemical production, or even converted into hydrogen.

- Hydrogen as a Fuel: Hydrogen can be produced through electrolysis or reforming, providing a clean energy source for power generation, particularly in fuel cells and gas turbines.

These advanced technologies in power plant materials, design, and operation not only enhance efficiency but also pave the way for sustainable, environmentally-friendly energy production, crucial for meeting future global energy demands while minimizing environmental impact.

Boilersinfo Boiler and Mechanical Power Digital Library

Boilersinfo Boiler and Mechanical Power Digital Library