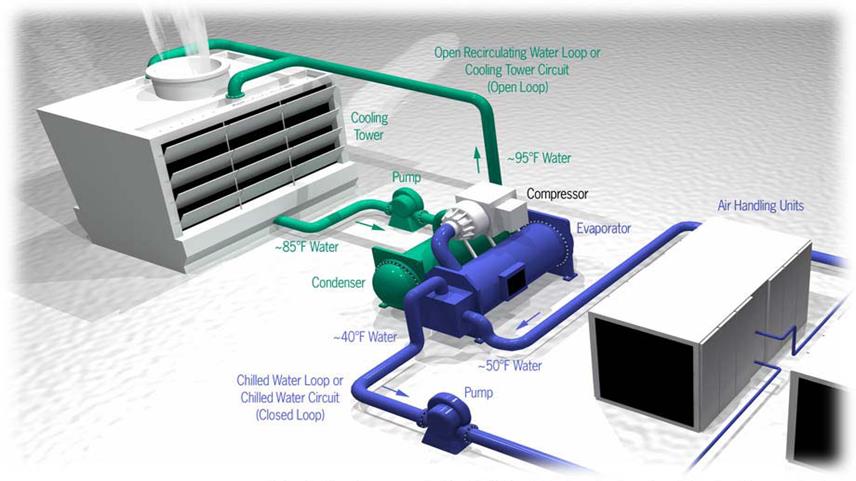

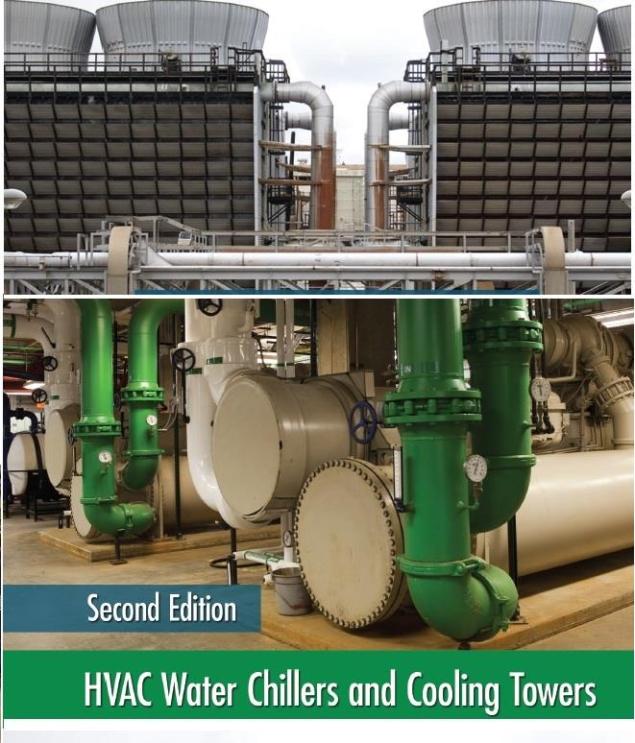

Modern buildings demand reliable climate control, and at the heart of many commercial and industrial HVAC systems lie water chillers and cooling towers. These two elements work together to manage heat, removing it from internal spaces and rejecting it to the outside environment. This article offers a clear and practical overview of how chillers and cooling towers function, their application, and what’s essential for optimal operation and efficiency.

The Role of Water Chillers in HVAC

Water chillers are specialized machines that remove heat from water via a refrigeration cycle. This chilled water is then circulated through air handling units or fan coil systems to provide cooling throughout a building.

The most common system used is the vapor compression cycle, where refrigerant circulates between a compressor, condenser, expansion valve, and evaporator. Heat is absorbed from the water in the evaporator and released to the atmosphere or a water loop in the condenser.

Some chillers use absorption refrigeration, especially in facilities where waste heat or steam is readily available. These chillers, though less common, are beneficial in energy integration and cogeneration systems.

Configurations and System Design

Water chiller systems can be simple or complex. A single-chiller system is common in small or mid-size buildings, while multi-chiller systems offer redundancy and capacity control for large facilities. Several pumping arrangements are used to circulate water, including primary-only, primary-secondary, and variable primary flow systems.

Key considerations during design and installation include:

- Chiller placement: Preferably in mechanical rooms or rooftops with good ventilation and accessibility.

- Pipe layout and insulation: Minimizes heat gain and pressure drop.

- Air removal and expansion control: Prevents air pockets and pressure-related damage.

- Water treatment: Prevents scaling, corrosion, and biological growth.

Pumps and Flow Management

Efficient water circulation is vital for chiller performance. Proper pump selection ensures the system meets the required flow rate and head pressure without wasting energy. Pump systems may operate under constant flow or variable flow strategies, the latter being more energy-efficient when paired with variable frequency drives (VFDs).

Smart Control and Energy Efficiency

Chiller systems are often managed through building automation systems that control:

- Start-up sequences

- Load-based capacity modulation

- Refrigerant flow regulation

- Chiller sequencing (if multiple units are installed)

- Supply temperature optimization

Advanced systems monitor performance in real-time, adjusting chiller operation based on cooling load demand and outdoor air conditions to improve energy efficiency.

Cooling Towers: Heat Rejection Made Efficient

Once heat is absorbed by the chiller system, it must be expelled. That’s where cooling towers come in. They work by bringing warm condenser water in contact with air, allowing a portion of the water to evaporate. This phase change removes heat from the system and cools the water, which then returns to the chiller.

Cooling towers are typically found in water-cooled chiller systems, and they offer high energy efficiency compared to air-cooled alternatives, especially for large-scale cooling.

Cooling Tower Components and Functionality

A cooling tower’s performance depends on its core components:

- Fill media: Increases the surface area for heat exchange (splash or film type).

- Fans and drift eliminators: Enhance airflow while minimizing water loss.

- Water distribution system: Ensures even spray over fill.

- Structure: Often made from wood, fiberglass, or metal, supporting internal components.

Proper selection of tower type (induced draft, forced draft, counterflow, crossflow) is critical depending on space, noise restrictions, and thermal load requirements.

Operation, Maintenance, and Troubleshooting

Chillers and cooling towers are high-value assets requiring careful commissioning, routine maintenance, and performance monitoring. Common operational tasks include:

- Checking refrigerant levels and compressor health

- Inspecting for vibration, noise, or leaks

- Monitoring water quality in both chilled and condenser loops

- Cleaning the fill media and strainers

- Lubricating motors and bearings

Issues such as reduced cooling capacity, unusual compressor cycling, or corrosion and scaling are often linked to system design flaws, improper flow rates, or neglected maintenance.

Thermal Energy Storage Integration

In advanced systems, thermal energy storage (TES) is used alongside chillers to shift cooling loads to off-peak hours. This can involve chilled water tanks, ice storage, or phase change materials, allowing chillers to operate more efficiently and reduce electricity costs.

Conclusion & 📘Book⬇️

HVAC water chillers and cooling towers form a dynamic duo for achieving effective and energy-efficient temperature control in buildings. Their performance hinges not only on proper sizing and installation but also on intelligent control, high-quality water treatment, and ongoing maintenance.

As buildings move toward net-zero energy goals and smarter operation, mastering the fundamentals and nuances of these systems is more important than ever.

Boilersinfo Boiler and Mechanical Power Digital Library

Boilersinfo Boiler and Mechanical Power Digital Library