A chiller is a machine that removes heat from a liquid via a vapor-compression or absorption refrigeration cycle. This liquid can then be circulated through a heat exchanger to cool air or equipment as required. Chiller is a compressor based equipment that cools and controls the temperature of a liquid unlike the air conditioners, which cools the air.

Types of Chiller

- On the basis of their functioning

1.Air-cooled Chiller

2.Water-cooled Chiller

- On the basis of driving force for refrigeration

1.Mechanical Compressor Chiller

2.Absorption Chiller

Air-cooled Chiller

Air-cooled chillers Absorb heat from process water and are transferred to the ambient air. They are mostly used in applications where the heat discharged is not a factor. They don’t need a cooling tower and condenser water pump. The maintenance of air-cooled chillers is less than water-cooled units. However, they consume 10% more power.

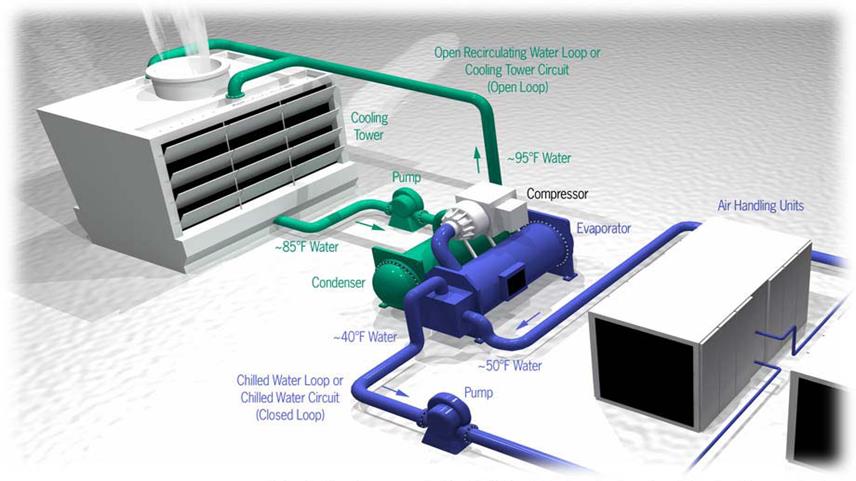

Water Cooled Chiller

Heat is absorbed from process water and is transferred to a separate water source like a river, pond, cooling tower, etc. Water-cooled chiller Mainly used at the places where the heat generated by air-cooled chillers poses a problem. Due to their less consumption of power they are usually preferred by those seeking optimum efficiency of power consumption. Water condensing units are more efficient than air condensed, often operating in the range of 15 EER or better (EER: energy efficiency ratio or BTU per hour per Watt energy consumption). Water-cooled chillers require a source of cooling water, such as cooling tower water, to extract heat from the refrigerant at the condenser and reject it to the ambient environment. The typical condensing temperature in a water-condensed chiller is 105°F.

Mechanical Compressor Chiller

At the heart of any chiller is the compressor. Compressors are used to increase the pressure of the refrigerant.

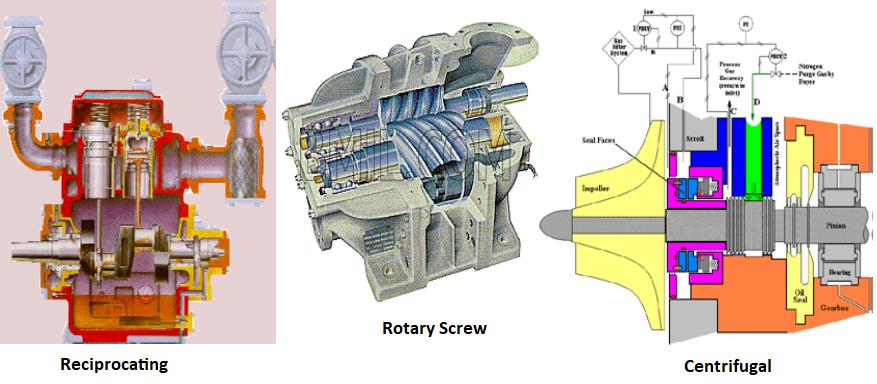

They are classified by the compressor type:

- Reciprocating

- Rotary screw

- Centrifugal

- Frictionless centrifugal.

Reciprocating

Similar to a car engine with multiple pistons, a crankshaft is turned by an electric motor, the pistons compress the gas, heating it in the process. The hot gas is discharged to the condenser instead of being exhausted out of a tailpipe. The pistons have intake and exhaust valves that can be opened on demand to allow the piston to idle, which reduces the chiller capacity as the demand for chilled water is reduced. This unloading allows a single compressor to provide a range of capacities to better match the system load. Capacities range from 20 to 125 tons.

Rotary Screw

The screw or helical compressor has two mating helically grooved rotors in a stationary housing. As the helical rotors rotate, the gas is compressed by direct volume reduction between the two rotors. Capacity is controlled by a sliding inlet valve or variable-speed drive (VSD) on the motor. Capacities range from 20 to 450 tons.

Centrifugal

lThe centrifugal compressor operates much like a centrifugal water pump, with an impeller compressing the refrigerant. Centrifugal chillers provide high cooling capacity with a compact design. They can be equipped with both inlet vanes and variable-speed drives to regulate control chilled water capacity control. Capacities are 150 tons and up.

Frictionless Centrifugal

lThis highly energy-efficient design employs magnetic bearing technology. The compressor requires no lubricant and has a variable-speed DC motor with direct-drive for the centrifugal compressor. Capacities range from 60 to 300 tons.

Absorption Chiller

The absorption cycle uses a heat-driven concentration difference to move refrigerant vapors (usually water) from the evaporator to the condenser. The high concentration side of the cycle absorbs refrigerant vapors (which, of course, dilutes that material). Heat is then used to drive off these refrigerant vapors thereby increasing the concentration again. Lithium bromide is the most common absorbent used in commercial cooling equipment, with water used as the refrigerant. Smaller absorption chillers sometimes use water as the absorbent and ammonia as the refrigerant. The absorbent is the material that is used to maintain the concentration difference in the machine. Most commercial absorption chillers use lithium bromide. Lithium bromide has a very high affinity for water, is relatively inexpensive and non-toxic.

Absorption chillers are available in two types:

Single Effect (Stage) Units: using low pressure (20 psig or less) as the driving force

Double Effect (2-Stage) Units: available as gas-fired (either direct gas firing or hot exhaust gas from a gas-turbine or engine) or steam-driven with high-pressure steam (40 to 140 psig).

Boilersinfo Boiler and Mechanical Power Digital Library

Boilersinfo Boiler and Mechanical Power Digital Library