Lifting equipment plays a pivotal role in the construction industry, facilitating the movement of heavy objects that would otherwise be challenging to transport manually. When used correctly, such equipment not only enhances efficiency but also mitigates the risks and dangers associated with manual lifting. However, improper use, faulty equipment, or incorrect handling can lead to grave consequences, including injuries, fatalities, and substantial property damage. In this article, we delve into the critical aspects of lifting equipment safety, offering insights into the hazards, planning, and risk assessment, safe work practices, and much more.

Hazards Associated with Lifting Equipment

Lifting equipment that is either defective, damaged, or mishandled can pose serious threats. The potential consequences extend beyond just physical harm to personnel; they encompass substantial damage to property and equipment. To ensure the well-being of both workers and the construction environment, adherence to proper lifting equipment safety protocols is imperative. Lifting equipment that is faulty, damaged, or used incorrectly has the potential to cause serious injury, even death, and result in significant property and equipment damage.

Planning and Assessment of Risks

Prior to using any piece of lifting equipment, there are a few basic fundamentals that need to be established and followed including:

- Knowing how the equipment should be used including recognizing faults and defects.

- The weight of the load or object to be moved.

- The Safe Working Limits (SWL) of equipment.

- All damaged and faulty equipment should be reported to your supervisor.

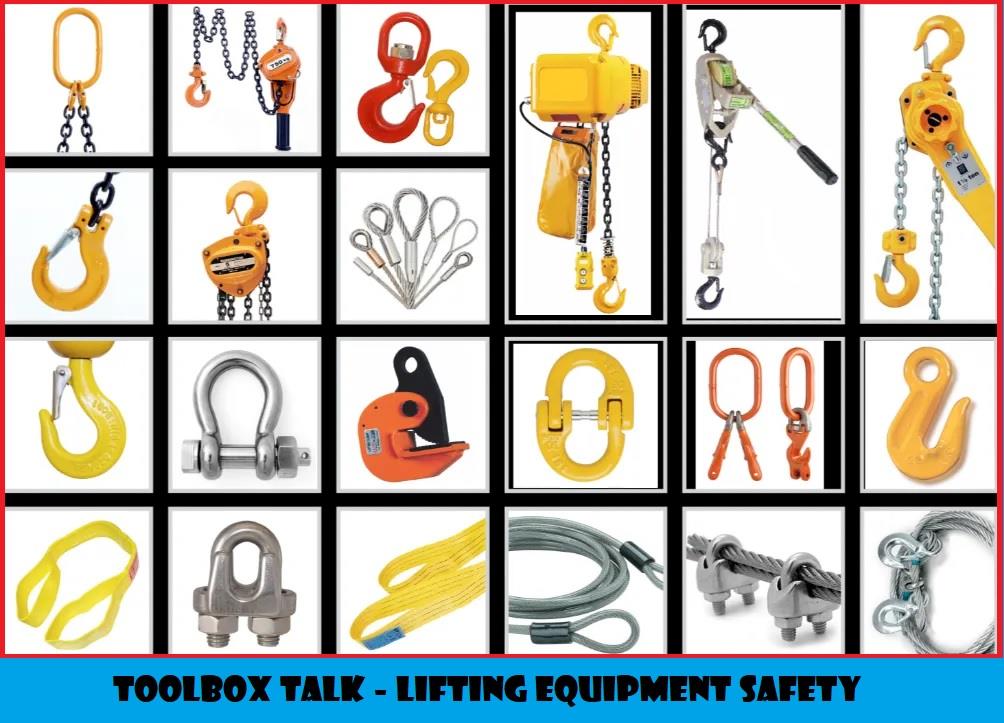

Safe Work Practices for Different Lifting Equipment

The following topics should be used as a guide when using various types of lifting equipment.

Steel Shackles – Shackles should never be overloaded.

Note: Consult your Supervisor or the shackle manufacturer’s tables to determine the maximum Safe Working Loads for individual shackles.

Shackles should be checked before being used, for:

- Distortion or elongation

- Physical damage

- Bent pins or pins of the incorrect size (note: Shackle pins must never be replaced with bolts).

- Report all faults to your supervisor for action.

- Damaged or faulty shackles must not be used as failure under load could lead to severe injury or death.

Chain Blocks/Lever Hoists

When using chain blocks/lever hoists:

Prior to use make sure:

- The weight of the object to be lifted has been determined.

- Hoisting and Rigging Safety Manual pdf

- The supporting structure (what you are going to hook it to) is capable of supporting the load.

- The hooks can be correctly secured/attached to the anchor point.

- Check hooks for:

* Safety latches – fitted and in good condition;

* Deformation or stretching of the hook opening ie. hook openings that are too wide.

* The condition of the swivel joints.

- Check chains for any sign of damage.

- Avoid exceeding Safe Working Loads (SWL) factors such as – side loading and friction need to be considered when determining the total loading being placed on the equipment.

Safe Working Practices that should be followed include:

- Lifting chains should not have any twists in them.

- Hooks should be free to move the direct pull. (Note: Hooks should not be ‘point’ loaded unless specifically designed for that purpose).

- Raise loads a small distance at first to ensure the brake is working correctly.

- Chain blocks/lever hoists that are used from crane hoods should be rated at twice the weight of the load to be lifted.

Note: The weight of the load should first be manually taken up with the chain block/lever hoist before the crane is used to lift. This will help prevent shock loading of the chain block.

Lifting Clamps

- Make sure you are fully aware of what each piece of equipment is designed for and what its limitations are. Contact your supervisor if you are unsure of how to use any piece of equipment safely.

- Avoid exceeding Safe Working Limits (SWL).

- Only use the equipment for its designed purpose.

- Prior to use:

Check lifting claims for obvious signs of damage including:

* Signs of distortion;

* Stretching or widening of openings

* Damage or excessive wear to cam and pad teeth and

* Cracks

Lifting Chains

- Store in clean dry locations.

- Avoid heating or allowing lifting chains to be heated. Heat can weaken the strength of the chain.

- Prior to using the equipment a visual inspection should be performed on chains, hooks, and fittings. Check equipment for

* Excessive wear * Nicks and chips

* Twisting * Gouges

* Distortion * Cracks

* The tendency for links to lock up.

* Stretching e.g chain links, opening up of hooks.

When lifting

- Protect chains from sharp edges and corners on loads being lifted.

- Take up slack in chains gently.

- Avoid lowering loads on top of chains.

- Avoid overloading chains.

- Faults that are identified should be reported to your supervisor for action.

Wire Rope

Where possible wire ropes should be used in preference to natural fibre or synthetic ropes.

Checks prior to use, examine for:

* Broken wires and strands * Wear

* Corrosion * Kinks

* Crushed or jammed strands * Distortion of rope or fittings

- Wire slings with an excessive number of broken wires should not be used.

- Select slings that are adequate for the job.

Make sure:

* The slings will not damage the load.

* The load being lifted will not damage the slings.

* Safe Working Loads (SWL) of the slings are not exceeded, taking into account the relevant rigging factors.

* Loads should not be left unattended whilst suspended or hanging from slings.

Synthetic Webb Slings

- Avoid exceeding the load capacity for the sling.

- Edge protectors should be used to avoid the need to sling around sharp or jagged edges.

- Store and keep synthetic slings away from chemical and corrosive substances e.g. dirt, grit, extreme heat, out of direct sunlight, and off the ground.

- Inspect slings each day prior to use checking for:

- * Any damage, cuts abrasions extending into the load-bearing core.

- * Excessive wear and tear.

- * Deterioration of stitching.

- Damaged slings should not be used. Report all damaged or faulty equipment to your supervisor. Defective slings should then be disposed of.

Ropes (Natural/Synthetic/Nylon/Manila)

- Chemicals and excessive exposure to heat and sunlight should be avoided where possible.

- Sharp or rough edges should be avoided and edge protectors used if required.

- Ropes should only be pulled or loaded in a straight line (direct line of pull)

- Safety Working Limits (SWL) should not be exceeded.

- Visually inspect ropes prior to use for signs of:

* Excessive wear;

* Rot and mildew:

* Cuts;

* Burns;

* Deterioration of fibers;

* Soft spots;

* Powdering.

If any doubt, contact your supervisor.

- Ropes should be stored in cool dry areas.

Note: Fiber rope slings should not be used in situations where wire slings or chains can be used.

Reporting of Faults/Hazards

Faulty or damaged equipment and unsafe situations should be rectified on the spot and/or reported to your supervisor. This enables action to be taken which will help prevent accidents from occurring.

FAQs About Lifting Equipment Safety

- Is lifting equipment safety relevant only to construction sites? No, lifting equipment safety is essential across various industries where heavy lifting is involved, including manufacturing and shipping.

- What should I do if I find a fault in lifting equipment during operation? Immediately cease using the equipment and report the fault to your supervisor for proper action.

- Can I replace shackle pins with bolts if they’re damaged? No, shackle pins should never be replaced with bolts, as this compromises the equipment’s integrity.

- Why is it important to avoid exceeding Safe Working Limits (SWL)? Exceeding SWL can lead to overloading, which may result in equipment failure and potential accidents.

- How frequently should I inspect lifting equipment for damage? Lifting equipment should be inspected before each use and periodically as recommended by safety guidelines.

Boilersinfo Boiler and Mechanical Power Digital Library

Boilersinfo Boiler and Mechanical Power Digital Library