Thermodynamics, Combustion, and Engines

Thermodynamics and combustion are integral to understanding and optimizing the performance of internal combustion engines (ICEs). These engines form the backbone of modern transportation, power generation, and industrial machinery. By examining the principles of thermodynamics, air and fuel flows, combustion processes, and engine systems, this article delves into the essential elements driving engine performance, efficiency, and sustainability.

Foundations: Internal Combustion Engines and Air Standard Cycles

Internal combustion engines operate on thermodynamic cycles that model energy transformations during the engine’s operation. Air standard cycles, including the Otto cycle for spark ignition engines, the Diesel cycle for compression ignition engines, and the Brayton cycle for gas turbines, provide a theoretical framework to analyze engine performance. These cycles illustrate processes such as compression, combustion, and expansion, enabling engineers to identify opportunities for efficiency improvements.

The study of thermodynamic properties—such as pressure, temperature, and enthalpy—is critical in understanding energy flow through an engine. These properties are used to calculate performance metrics like thermal efficiency and work output, offering insights into how engines convert fuel energy into mechanical power.

Flow Dynamics: Air, Fuel, and Compressible Flows in Engines

Efficient air and fuel flow within an engine is crucial for optimal performance. Compressible flow principles govern the behavior of gases under varying pressures and temperatures as they move through engine components like intake manifolds, turbochargers, and exhaust systems.

The air-fuel mixture is precisely controlled to achieve the desired combustion characteristics. This balance directly impacts power output, fuel efficiency, and emissions. Advanced systems like direct fuel injection and variable valve timing enhance this process, ensuring that engines operate efficiently across various load conditions.

Combustion, Emissions, and Fuels

Combustion is the core process where chemical energy in the fuel is released and converted into heat. This process must be meticulously managed to maximize energy conversion while minimizing emissions. Combustion in ICEs varies depending on the engine type; spark-ignition engines rely on a controlled spark, while compression-ignition engines depend on high-pressure air temperatures for ignition.

Emissions control is a critical aspect of modern engine design. Combustion generates pollutants like nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbons. Technologies such as catalytic converters, particulate filters, and exhaust gas recirculation (EGR) systems are employed to meet stringent environmental standards.

The choice of fuel significantly influences combustion efficiency and emissions. Traditional fuels like gasoline and diesel are being supplemented with alternative fuels such as biodiesel, ethanol, and hydrogen. These alternatives not only reduce reliance on fossil fuels but also support cleaner combustion processes, aligning with global sustainability goals.

Engine Turbomachinery and Heat Transfer

Turbochargers and superchargers are critical components of engine turbomachinery, enhancing engine performance by increasing the amount of air entering the combustion chamber. This boost allows for more fuel to be burned, increasing power output without enlarging engine size. Turbomachinery design involves a detailed understanding of compressible flows and thermodynamics to ensure optimal performance.

Heat transfer plays a pivotal role in engine operation. Excess heat must be efficiently managed to prevent damage to engine components and maintain performance. Advanced cooling systems, thermal barriers, and heat exchangers are used to control temperatures within the engine. Innovations in materials and coatings further enhance thermal management, ensuring engine durability and reliability.

Performance, Control Systems, and Engine Design

Engine performance is assessed through metrics like brake thermal efficiency, power output, and specific fuel consumption. These metrics guide the optimization of engines for various applications, from passenger vehicles to power generation.

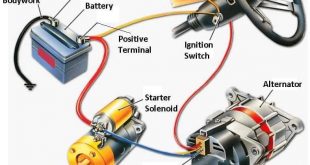

Engine control systems are essential for maintaining performance under varying conditions. Modern engines rely on electronic control units (ECUs) to regulate fuel injection, ignition timing, and exhaust aftertreatment systems. These systems use sensors and algorithms to adapt engine operation dynamically, ensuring optimal performance and compliance with emissions standards.

Design and optimization efforts focus on improving engine efficiency, reducing weight, and enhancing reliability. Advanced computer-aided design (CAD) tools and simulation software allow engineers to model and test engine components virtually, reducing development time and costs.

Advanced Technologies and Future Trends

The future of internal combustion engines is being shaped by advanced technologies and a shift toward sustainability. Hybrid powertrains, combining ICEs with electric motors, are becoming more prevalent, offering improved efficiency and reduced emissions. Renewable energy sources, such as biofuels and synthetic fuels, are also being integrated into engine systems to reduce dependency on fossil fuels.

Research into advanced combustion strategies, such as homogeneous charge compression ignition (HCCI) and low-temperature combustion (LTC), is driving innovation in engine design. These technologies aim to improve efficiency and reduce emissions by optimizing the combustion process.

Looking ahead, engines are expected to play a role in renewable energy systems and power generation cycles. Developments in energy storage, hydrogen combustion, and integration with renewable energy sources will redefine the landscape of engine technology.

Conclusion

Thermodynamics, combustion, and engine systems form the foundation of modern power generation and transportation. By understanding and optimizing these principles, engines can deliver greater efficiency, lower emissions, and enhanced performance. As alternative fuels, advanced technologies, and sustainable practices reshape the industry, internal combustion engines will continue to evolve, remaining a vital component of the global energy mix.

Boilersinfo Boiler and Mechanical Power Digital Library

Boilersinfo Boiler and Mechanical Power Digital Library