Water Chemistry Practices in Thermal Power Stations

Water chemistry plays a critical role in the safe, efficient, and reliable operation of thermal power stations. Proper chemical control not only maximizes equipment life and thermal efficiency but also minimizes corrosion, scaling, fouling, and environmental impact. This article provides an in-depth overview of water treatment and testing practices within thermal power plants.

1. The Role of Chemistry in Power Plant Operations

In thermal power plants, water chemistry governs the health of the entire feedwater-steam-condensate cycle and the cooling water systems. Proper chemistry ensures:

- Reduced corrosion and scaling

- Optimal heat transfer

- Minimal downtime

- Compliance with environmental standards

2. Water Treatment Chemistry

Water entering the plant contains impurities like dissolved salts, oxygen, silica, and organics that can damage boiler tubes, turbines, and condensers. Treatment processes are designed to remove these impurities before water enters critical components.

Demineralization (DM)

Demineralization involves the removal of dissolved salts through ion exchange columns:

- Cation exchanger removes Ca²⁺, Mg²⁺, Na⁺

- Anion exchanger removes Cl⁻, SO₄²⁻, NO₃⁻

- Mixed bed exchanger provides final polishing for high-purity water

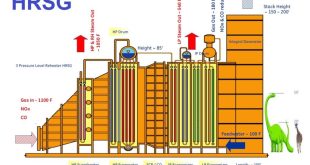

3. Boiler Feed and Steam Cycle Chemistry

Boiler feedwater requires precise conditioning to prevent corrosion and scale:

- Oxygen scavengers (e.g., hydrazine) to eliminate dissolved O₂

- pH control agents like ammonia or morpholine to maintain alkaline conditions

- Phosphate treatment for internal scale control

- Condensate polishing using resins or filtration to remove corrosion products

4. Cooling Water Chemistry

Cooling systems use large volumes of water and are susceptible to:

- Scaling from calcium and silica

- Corrosion due to dissolved oxygen or low pH

- Biological fouling from microbial growth

Treatment includes:

- Antiscalants

- Biocides

- Corrosion inhibitors (e.g., molybdates, phosphonates)

In seawater-cooled plants, special materials and antifouling measures are necessary to resist high chloride levels and marine growth.

5. Chemistry of Water Pollution

Power plants must manage effluents and meet regulatory limits on:

- Chemical Oxygen Demand (COD)

- Biochemical Oxygen Demand (BOD)

- Heavy metals

- Oil and grease

Proper water chemistry management reduces the environmental footprint and supports sustainable operations.

6. Water Testing Methods

Regular monitoring is essential. Parameters tested include:

- pH – Measured using pH meters (glass electrode method)

- Alkalinity/Acidity – Via titration with acid/base

- Total and Calcium Hardness – Using EDTA titration

- Dissolved Oxygen – Using Winkler’s method or online DO meters

- COD/BOD – Chemical or biological oxidation tests

- Total Organic Nitrogen – Kjeldahl method or online analyzers

7. Reverse Osmosis (RO) in Water Treatment

RO systems are widely used in power stations for producing high-purity water. Working principle:

- High pressure forces water through semi-permeable membranes

- Salts and impurities are retained, producing permeate (pure water) and concentrate (reject stream)

Pre-treatment with filters and antiscalants is essential for membrane longevity.

8. Instrumental Methods for Water Analysis

Direct Readout Instruments

- Online conductivity meters for ionic contamination

- Online silica analyzers to prevent steam turbine damage

- Online sodium analyzers for early leak detection

- Online TOC analyzers for organic content

Colorimetric Methods

- Test kits with color change indicators for:

- Chlorine

- Iron

- Phosphate

- Ammonia

- Nitrate

These are quick, easy to use, and suitable for field applications.

9. Case Studies from Thermal Power Stations

Several plants have improved reliability through disciplined water chemistry:

- A 500 MW unit in India reduced condenser fouling by switching to film-forming amines

- A coastal plant minimized seawater corrosion using advanced titanium condenser tubes

- A North American plant improved boiler efficiency by adopting online silica and sodium monitoring

These examples show how good chemistry translates into better performance and reduced downtime.

10. Equipment-Specific Chemical Needs

Every component in the water-steam cycle has specific chemistry considerations:

- Boiler drum – pH, phosphate balance, silica

- Economizer and superheater – corrosion inhibitors

- Turbine – silica and sodium control in steam

- Condenser – oxygen control and condensate polishing

Each requires tailored monitoring and chemical treatment.

Boilersinfo Boiler and Mechanical Power Digital Library

Boilersinfo Boiler and Mechanical Power Digital Library