Large Boilers in power plants are fitted with soot blowers, which are tools to keep the outside surface of the tubes clean and free from material or ash that would have a detrimental effect on the heat transfer surface. The blowing fluid is generally steam and the frequency of operation depends upon the type of fuel being used. The flue gas temperature is an indicator of the need for soot blowing. A higher than normal flue gas temperature for a given steam load at normal firing conditions indicates that the convection section tubes are becoming fouled and the proper heat transfer is not taking place.

Types of Soot-Blowers

There are two main types of soot blowers:

- Fixed or stationary soot blowers

- Retractable soot blowers.

Wall blowers

Short Retractable Soot Blowers (SRSB)

Sonic Soot Blowers etc.

A stationary soot blower, as the name implies, is a fixed tube with holes. The holes are positioned to blow steam between the tubes.

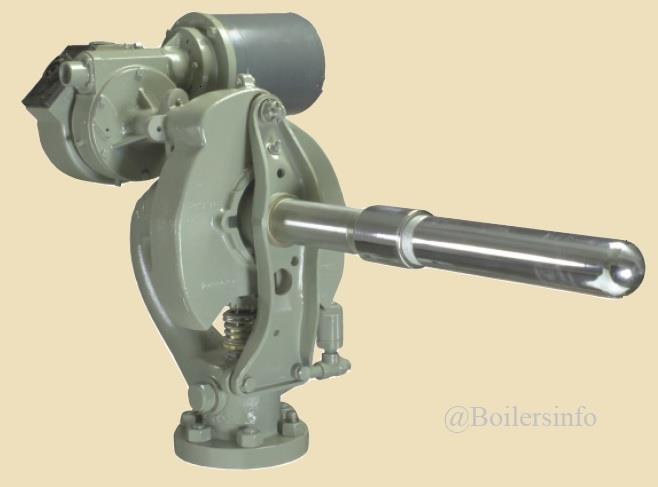

Retractable soot blowers – the lance is operated by electric motors. One motor rotates the lance at a constant speed while a two-speed motor handles the travel. A slow speed is used when the lance is going in and a much faster speed is used as it retracts. This is to save time and steam.

One method of operation of the retractable soot blower is on automatic control of flue gas temperature. There is a disadvantage to this in that during soot blowing, a temperature reduction occurs because the steam used for soot blowing cools the tubes and therefore the blowing could cause quite a drop in steam production at an inconvenient time. It must be emphasized that the steam traps on the lines to the soot blowers must be operational so that condensate is not blown onto the tubes.

Soot Blower Operation

Normally the lance-type long retractable soot blower is a component part of a larger soot blower plant. Normally soot blower consists of piping, shut-off and drain valves, soot blowers, and control. The latter controls the flow of the blowing program and shall include the interlocks required for the protection of the boiler and soot blower, e.g. monitoring of the pressure, temperature of the blowing medium, and operating times of the soot blowers. Normally the soot blowers are operated from a control cabinet or switchboard in the control room.

The frequency of soot blowing depends on the type and extent of contamination of the heating surfaces. The heating surfaces within the blowing area of the soot blowers are to be visually checked at regular intervals within the first period after commissioning. They also have some disadvantages and challenges associated with their use like,

1. Energy Consumption

2. Wear and Tear

3. Maintenance Requirements

4. Steam or Air Consumption

5. Boiler Shutdowns or Boiler blackout conditions due to wrong operation etc.

Despite these disadvantages, soot blowers are still crucial for maintaining boiler efficiency and preventing damage from deposits.

The purposes of soot blowers are:

1. Heat Transfer Efficiency

2. Preventing Corrosion

3. Reducing Fuel Consumption

4. Maintaining Steam Quality

5. Extending Equipment Life

Soot Blowers play a critical role in ensuring the efficient and safe operation of solid fuel-fired boilers by keeping heat exchange surfaces clean and optimizing heat transfer.

Boilersinfo Boiler and Mechanical Power Digital Library

Boilersinfo Boiler and Mechanical Power Digital Library