Boiler Alkali boil out is carried out to remove material such as lubricants, oil, and rust. During the manufacturing of seamless steel tubes, mill scales are bound to be formed, and some of these can remain inside. During fabrication and erection of the pressure parts, some amount of oil and lubricants can also. get into the tube surface apart from tube weld slag and other materials.

Before commencing the alkali boil out, the boiler is flushed with hot and cold water to remove loose debris and sand. During this process, the drum internals should not be in position and care should be taken to avoid water into the superheaters system.

Prerequisites alkali boil out of the boiler

the following prerequisites/inputs have to be ensured.

- Mechanical completion of boiler including auxiliaries and piping.

- Completion of hydraulic test activities and refractory dry-out.

- Readiness of electrical and instrumentation controls and adequate illumination in and around the boiler house. (Electrical power for motorized valves and gauge glass illuminator.)

- Availability of DM water through boiler feed water pumps.

- Readiness of sample collection system and availability of required chemicals for the alkali boil out.

- Boiler ready for light up with thermal expansion provisions.

- Availability of lab facilities to test the water. (pH and oil detection)

- Readiness of chemical dosing system.

- All the debris is removed from the Boiler and all the access doors in the boiler should be closed.

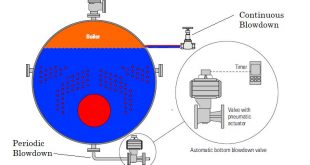

- Good working drum level gauge glass with illuminator assembly, Boiler drum pressure gauge, safety /relief valves with gags or hydrostatic plugs are removed, CBD, IBD, and all drain valves in good working conditions, water level control and associated alarms, cooling water piping and air piping, furnace pressure gauge and Temperature indications for flue gas, feed water, and steam line.

- During alkali boil out, transmitters connected to the steam drum and steam piping is isolated to avoid any damage to transmitters due to alkali.

- Blow-down and drain connections are terminated in a safe location.

Alkali out Chemical quantity per blowing should be available Tri sodium phosphate, Caustic soda, and Detergent.

Procedure for 1st Stage boil-out

Fill the specified quality feed water 50mm below the steam drum manhole rim. The exact quantity of chemicals is to be dissolved in DM water externally in a container, and the concentrated solutions so prepared are to be poured into the drum through the manholes. The entire quantity of chemicals has been dissolved and poured into the drum. Close the manhole and fill the drum to the normal level. Increase slowly the heat input to the boiler to raise pressure to 30psi (2.1 kg/cm2 (g). A good flow of steam from air-release valves will be noticed. Up on seeing this, close the air release valve. Continue increasing the pressure to 10kg/cm2 (g). Maintain pressure at l0kg/ cm2 (g) for a period of 16 hours. This will ensure rapid circulation of water through the boiler. Give blow down at every 2 hours interval from water wall drains for one minute each. Extinguish the fire and blow down the water from the boiler manifolds individually for a period of 2-3 minutes each. Allow the boiler to cool down naturally. When pressure comes to 2.5kg/cm2 (g) with manifolds closed, blow down steam drum water, until water level falls below gauge glass. Following this, the entire boiler water can be blown down as quickly as possible using all manifold drains and drum blow-down drains. This way evacuate the water before any dirt or oil has time to settle down. When the pressure falls to 30 psi (2.1 kg/ cm2 ) open air release valves. With blow-down and drain valves open wash the drum, Manifolds, and tubes with high-pressure clean water to wash out any remaining sediment.

Procedure for 2nd Stage boil-out

Follow the above procedure, increase the pressure up to 20kg/ cm2 (g), and carry boil-out operation by maintaining this pressure for a period of 12 hours. The pressure of 20kg/ cm2 (g) is to be maintained by controlling the fuel firing and modulation of the start-up vent. During this process, the normal water level in the drum is to be ensured. Operate IBD for 10 seconds every one hour. Blowdown through low point drains by opening the valves, one by one but one at a time for one-minute intervals each means while ensuring the drum level. Blow down the water wall drains every two hours for one minute. Blow down the system at an interval of every 2 hours. After every blow-down operation collect drum water samples and analyze for phosphate and oil content. Replenish phosphate concentration through HP dosing system as and when the residual value goes to less than half of the concentration maintained at the start of the process. Samples are taken from the blowdown and analyzed for pH, alkalinity, oil content, and conductivity. The quantity of oil and grease found in the boiler water determines the duration of the boil-out. Continue the boil-out operation till the oil content in the sample collected show less than 5ppm.

Completion of Boil-out

When analysis confirms the oil presence in the samples is equal to or less than 5ppm the boil-out operations are treated as completed. For confirmation, it is suggested to collect 3 samples within 5 minutes of each other and check the consistency of the results.

Post Boil-out Operation

Operate each blow-down and drain valve successively for a few seconds to discharge any accumulated sludge. Repeat several times, meanwhile maintaining drum level. Allow the boiler to cool down naturally. When the drum pressure comes to 2kg/cm2 (g) open all air release valves. When the drum pressure drops to atmospheric, drain the boiler by opening all valves on the drain headers. Fill the boiler up to the drum to the required level and back flush the superheaters into the drum till the sample collected from the superheater off take tube mouth in the drum shows a low conductivity and high clarity. After completion of the Alkali boil out and the boiler is considerably cooled, flush the boiler with DM water till the system is free from alkali solution (i.e.) the pH value of effluent should be equal to that of the DM water used for flushing.

Final Inspection

After the boiler has cooled down completely, open all manhole doors and remove all manifold inspection caps to inspect the internal surfaces. Re-weld the end caps on headers as per recommended procedures and carry out necessary NDT and stress reliving as applicable. Accumulated dirt and sludge should be scrapped out in drums, manifolds, and tubes washed through high-pressure clean water. Examine all heating surfaces and gas passes of the boiler for excessive

soot deposits resulting from low firing rates employed in Boil out. Clean manually the soot deposits. Check all refractories for any cracks. Check for any ash accumulation in any area. Check that expansion joints are set correctly and that expansion clearances are adequate.

NOTE – Boiler water contains chemicals, which are hazardous to human safety, and hence safe disposal is necessary.

Boilersinfo Boiler and Mechanical Power Digital Library

Boilersinfo Boiler and Mechanical Power Digital Library