Boiler Efficiency and Safety: A Guide for Managers, Engineers, and Operators Responsible for Small Steam Boilers

Boiler systems are the heart of many industrial operations, providing steam for heating, power generation, and various manufacturing processes. In small steam boilers, typically up to 10 MW output, achieving high efficiency and maintaining safety standards are essential not only to save fuel and money but also to ensure smooth operation. This guide aims to help managers, supervisors, and operators achieve both efficiency and safety in their operations. By following practical steps and guidelines, significant improvements in fuel savings, boiler performance, and safety can be achieved.

1. Safety of Boiler

Safety is the top priority when operating any steam boiler, particularly in smaller systems where the risk of failure or malfunction can lead to significant operational disruptions or even dangerous incidents. Boilers operate under high pressure and temperature, making them potentially hazardous if not maintained and operated properly.

- Key Safety Considerations:

- Pressure Relief Valves: Ensure that pressure relief valves are functioning and regularly tested to prevent overpressure.

- Water Level Monitoring: Maintain proper water levels to avoid dry firing, which can lead to severe damage.

- Safety Shutdown Mechanisms: Boilers should be equipped with automatic shutdown mechanisms in case of malfunction.

- Routine Inspections: Regular inspections and safety checks should be conducted to detect leaks, corrosion, or malfunctions.

2. Types and Selection of Fuel Oils

The choice of fuel is critical to the boiler’s efficiency, operational cost, and emissions. Fuels used in small steam boilers typically include heavy oil, light oil, and natural gas.

- Factors Affecting Fuel Selection:

- Cost and Availability: Choose the fuel that is both economically viable and readily available.

- Combustion Efficiency: Fuels should be selected based on their ability to combust cleanly and efficiently to minimize emissions and reduce wastage.

- Environmental Regulations: Consider the environmental impact of the fuel, particularly in terms of sulfur content and CO2 emissions.

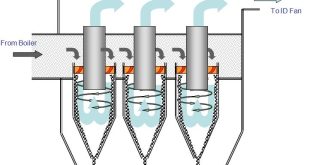

3. Combustion Processes and Monitoring

The combustion process directly impacts the boiler’s efficiency and emissions. Optimizing combustion involves controlling the fuel-to-air ratio and ensuring the correct temperature and pressure for maximum heat transfer.

- Monitoring Parameters:

- Flue Gas Analysis: Use flue gas analyzers to measure oxygen (O2), carbon monoxide (CO), and carbon dioxide (CO2) levels. Maintaining a low CO level indicates good combustion.

- Excess Air: Monitoring excess air ensures that enough oxygen is provided for combustion without wasting energy.

- Burner Tuning: Proper tuning of the burners helps maintain optimal fuel efficiency and minimize pollutants.

4. Combustion in Practice

In practice, combustion may be affected by several factors such as fuel quality, burner design, and operating conditions. Consistent monitoring and adjustments can keep combustion at an optimal level.

- Best Practices:

- Regularly clean and inspect burners to avoid blockages and ensure smooth fuel flow.

- Implement scheduled burner tests to check for efficiency losses or operational problems.

- Optimize burner flame patterns and fuel atomization to ensure a complete and efficient combustion process.

5. Water Treatment

Proper water treatment is crucial for boiler efficiency and safety. Impurities in water can cause scaling, corrosion, and fouling in the boiler system, leading to reduced heat transfer and increased fuel consumption.

- Water Treatment Steps:

- Deaeration: Remove dissolved gases like oxygen that contribute to corrosion.

- Softening: Reduce hardness to prevent scaling on boiler tubes and other surfaces.

- Chemical Treatment: Use chemicals to control pH and minimize the formation of scale and sludge.

- Regular Testing: Perform regular tests to monitor water quality and adjust treatment accordingly.

6. Boiler Operations

Efficient boiler operation is achieved through understanding key parameters such as feedwater temperature, steam pressure, and load conditions. Proper operation also requires clear communication and coordination between operators, maintenance staff, and management.

- Operational Best Practices:

- Monitor and Control Load Fluctuations: Load management is essential to prevent energy waste and stress on the boiler system.

- Steady Combustion: Ensure that the burner operates smoothly by maintaining steady combustion.

- Minimize Thermal Cycling: Avoid excessive cycling (frequent startups and shutdowns), which can cause thermal stress and reduce equipment lifespan.

7. Maintenance

Regular and thorough maintenance is necessary to keep small steam boilers operating efficiently and safely. Preventive maintenance reduces the likelihood of unexpected breakdowns and extends the boiler’s service life.

- Maintenance Procedures:

- Routine Inspections: Check key components like burners, pressure relief valves, and steam separators regularly.

- Cleaning: Regularly clean burner nozzles, tubes, and other parts to remove soot and debris.

- Water Treatment Maintenance: Keep the water treatment system in optimal condition by regularly replacing chemicals and monitoring water quality.

- Calibration: Ensure that all pressure, temperature, and flow sensors are calibrated for accurate readings.

8. Efficient Use of Steam

Once steam is generated, it must be used efficiently to maximize its potential. This involves proper distribution and control of steam across the system and preventing steam leaks, which can lead to significant energy loss.

- Efficiency Tips:

- Insulate Steam Pipes: Ensure steam pipes are well-insulated to minimize heat loss during distribution.

- Optimize Steam Pressure: Adjust steam pressure according to the demand to avoid excessive fuel consumption.

- Use Steam Traps: Install steam traps to remove condensate and prevent steam loss, ensuring that only useful steam is used.

9. Training Courses and Material

An essential element of maintaining both boiler efficiency and safety is proper training for all personnel involved in boiler operations. Well-trained staff are better equipped to manage the boiler safely, perform maintenance tasks, and optimize performance.

- Training Best Practices:

- On-the-job Training: Provide hands-on training for operators to familiarize them with boiler operation, troubleshooting, and maintenance.

- Safety Awareness: Ensure that training includes thorough coverage of safety procedures and emergency protocols.

- Continuous Learning: Encourage operators and engineers to attend refresher courses to stay updated on new technologies and regulatory changes.

Conclusion

By implementing the principles outlined in this guide, managers and operators of small steam boilers can achieve substantial improvements in efficiency, reduce operating costs, and ensure safety. Regular monitoring, preventive maintenance, and proper training are fundamental to ensuring the long-term success of boiler systems. With a strong focus on safety and efficiency, small steam boiler operations can be optimized to run more smoothly, reliably, and economically.

Boilersinfo Boiler and Mechanical Power Digital Library

Boilersinfo Boiler and Mechanical Power Digital Library