Improving Steam System Performance

Steam System Basics

Why Steam?

Steam is a vital utility in industries across the globe due to its versatility, efficiency, and cost-effectiveness. It serves as an energy carrier, capable of transferring heat efficiently over long distances and at high pressures. Steam is used for various applications, including heating, power generation, sterilization, and mechanical work, making it indispensable in sectors such as manufacturing, healthcare, and energy production. Its unique properties, such as high heat content and ease of generation, make it an ideal medium for thermal processes.

Steam’s flexibility stems from its ability to adapt to various temperature and pressure requirements. This adaptability allows industries to tailor steam usage to specific operational needs, ensuring optimal performance. Furthermore, the ability to condense steam into water and reuse it enhances its efficiency, making it a sustainable energy solution. Steam’s long history as a reliable energy carrier underscores its importance in industrial innovation and modern processes.

Steam System Operation

A steam system is a network designed to generate, distribute, and utilize steam effectively while minimizing losses and ensuring safety. Proper operation of these systems ensures that energy is not wasted, and the processes relying on steam receive consistent supply and quality. The primary components of a steam system include:

Generation: Steam is produced in boilers or heat recovery steam generators, where water is converted into steam through thermal energy. Boilers are engineered to operate efficiently while accommodating the varying demands of industrial operations.

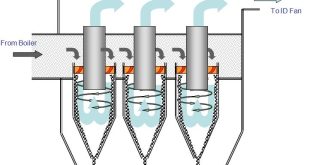

Distribution: The generated steam is transported via insulated pipes to end-use points. This network must be well-maintained to avoid leaks, pressure drops, and heat loss.

End Use: Steam is used in numerous applications, including heating spaces, driving turbines, or sterilizing equipment. Each application demands precise pressure and temperature control to meet operational requirements effectively.

Generation

The generation process starts with boilers, which come in various designs tailored to industry needs. Fire-tube boilers are suited for low-to-medium pressure systems, while water-tube boilers accommodate high-pressure and high-temperature demands. Efficient operation relies on the following practices:

- Regular Maintenance: Inspecting and cleaning boilers to ensure optimal combustion and heat transfer.

- Water Treatment: Preventing scaling and corrosion through proper treatment of feedwater.

- Emission Management: Complying with environmental standards by installing emission control systems, such as scrubbers or selective catalytic reduction units.

Distribution

The distribution system ensures steam reaches its destination with minimal loss. Challenges in distribution arise from insufficient insulation, corrosion, and pressure imbalances. To maintain an efficient distribution network:

- Use high-quality materials resistant to high pressure and thermal stress.

- Insulate all piping, valves, and fittings to reduce heat loss.

- Install pressure regulators and flow meters to monitor system performance.

Maintenance of steam traps is critical in removing condensate without allowing steam to escape. Regular inspection of traps prevents energy losses and ensures smooth system operation.

Performance Improvement Opportunities

Overview

Industrial facilities often overlook the potential for performance improvements in their steam systems. Identifying and addressing inefficiencies yields benefits such as reduced energy consumption, lower emissions, and extended equipment life. A comprehensive approach focuses on both system-wide and component-level optimizations.

Systems Approach

Adopting a systems approach involves analyzing the entire steam cycle from generation to end-use. This method provides a holistic view, enabling stakeholders to identify root causes of inefficiencies and prioritize actions that yield the highest returns. Steps to implement a systems approach include:

- Conducting detailed energy audits to assess the system’s current performance.

- Utilizing advanced monitoring tools to collect data on pressure, temperature, and flow rates.

- Integrating energy management systems to track performance metrics in real time.

Common Performance Improvement Opportunities

- Boiler Upgrades: Replacing outdated boilers with high-efficiency models can dramatically reduce fuel consumption. Modern boilers incorporate features such as automated controls and enhanced heat recovery systems.

- Condensate Recovery Systems: Recycling condensate conserves energy by reducing the need to heat fresh water. High-efficiency condensate return systems can also minimize water treatment costs.

- Optimized Insulation: Proper insulation reduces heat loss and ensures consistent steam delivery. Regularly inspect insulation for damage and promptly repair any deficiencies.

- Steam Trap Maintenance: Failed steam traps lead to significant energy losses. Implementing a routine inspection schedule ensures that traps function correctly and condensate is removed efficiently.

- Load Balancing: Managing steam demand by staggering processes and using storage systems prevents pressure fluctuations and enhances system stability.

Best Practices Steam System Improvement Tools

Implementing best practices requires the use of advanced tools and methodologies. Organizations can adopt:

Energy Audit Software: Digital tools for conducting thorough system analyses and identifying inefficiencies.

Simulation Models: Creating virtual models of steam systems to test various scenarios and optimize configurations.

Training Programs: Empowering personnel with knowledge of steam system operations and maintenance best practices ensures sustained improvements.

Benchmarking Metrics: Comparing system performance against industry standards helps identify areas for enhancement and track progress over time.

Programs, Contacts, and Resources

OIT and BestPractices

The Office of Industrial Technologies (OIT) under the U.S. Department of Energy promotes energy-efficient practices through its BestPractices program. This initiative offers technical resources, training, and financial incentives to support industries in achieving steam system optimization.

The program emphasizes:

- Reducing greenhouse gas emissions through improved energy efficiency.

- Enhancing productivity by minimizing system downtime.

- Providing tools for comprehensive system assessments and performance monitoring.

Directory of Contacts

Industries seeking guidance can benefit from engaging with experienced professionals. Key contacts include:

Steam System Engineers: Experts who specialize in designing efficient steam networks tailored to specific industrial needs.

Energy Service Companies (ESCOs): Organizations that provide turnkey solutions for energy optimization projects.

Equipment Suppliers: Companies offering state-of-the-art boilers, steam traps, and other essential components.

Resources and Tools

A wide array of resources is available to assist industries in optimizing their steam systems. These include:

- Publications: Technical manuals, white papers, and industry reports on steam system management.

- Software: Tools for energy modeling, system design, and performance analysis.

- Webinars and Workshops: Educational programs to build expertise in steam system operations and maintenance.

- Financial Assistance Programs: Grants, tax incentives, and rebates to support energy efficiency investments.

Conclusion

Optimizing steam system performance is a critical step toward achieving energy efficiency, reducing costs, and minimizing environmental impact. By focusing on system-wide improvements, industries can unlock significant benefits, including enhanced productivity, lower operational expenses, and compliance with sustainability goals.

Understanding the basics of steam systems, leveraging modern tools, and committing to best practices are essential for long-term success. As industries continue to innovate, maintaining efficient steam systems will remain a cornerstone of operational excellence and environmental stewardship.

Boilersinfo Boiler and Mechanical Power Digital Library

Boilersinfo Boiler and Mechanical Power Digital Library