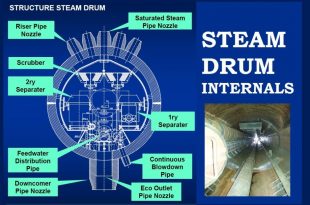

In the water tube boiler the upper drum (Boiler steam drum) provides for separation of steam from water. It also provides liquid holdup capacity (typically 10 to 60 seconds) to allow for a dynamic response to load changes without losing liquid in the downcomer and riser tubes. The size of the …

Read More »Boiler articles

Boiler inspection Procedure requirement and Recommendations

Pressure vessels and Boiler Inspection are done to determine the amount of maintenance required to have equipment operate properly until the next turnaround. A comprehensive equipment history must be maintained that includes conditions found during inspection and testing, maintenance work done, changes made, and date of each. ASME Code Standards …

Read More »Boiler Design Basic Steps

Boiler design is the process of designing boilers used for various purposes. The main function of a boiler is to heat water for steam generation. Steam produced can be used for a variety of purposes including space heating, sterilization, drying, humidification, and power generation. The temperature or condition of steam required for …

Read More »Boiler Water Treatment Basic

Boiler Water Treatment is necessary to Produce quality steam on demand and depends on properly managed water treatment to control steam purity, deposits, and corrosion. There are two main types of boiler feed water treatment Internal boiler Water Treatment method and external boiler water treatment. A boiler is the sump …

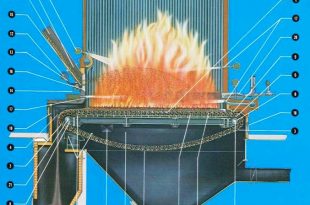

Read More »Stoker Fired Boiler types of stokers

Stoker Fired Boiler are classified according to the method of feeding fuel to the furnace and by the type of grate. The main types of stokers are: Chain-grate or travelling-grate stoker Spreader stoker boiler Travelling Grate or chain grate Stoker Boiler In Travelling Grate boiler coal is fed at one …

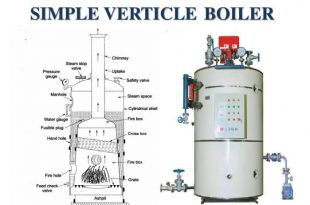

Read More »Simple Vertical Boiler Working

A vertical boiler is a type of steam boiler that is designed with a vertical cylinder shape. Vertical boilers are often used in small- to medium-sized facilities, such as schools, hospitals, and small industrial plants, where space is at a premium. This is the simplest type of fire tube boiler. …

Read More »Package Boiler

The packaged boiler is so called because it comes as a complete factory-assembled Package with all mountings, accessories and control instrumentation are installed on it. Once it delivered to site, boiler requires only the steam, feed water pipe line. fuel supply connections and electrical connections to be made for package …

Read More »Electrostatic precipitator meaning

Electrostatic precipitator meaning an efficient flue gas cleaning device ESP means Electrostatic precipitator is a device have been used for over half a century to control particulate emissions or dust cleaning device in many industries like power plants boiler ,cement and steel mills. Electrostatic precipitators have a very high collection …

Read More »Steam Blowing Procedure

This Steam Blowing procedure is intended to provide general application guidance and establish controls during Steam Blowing of piping and equipment. The purpose of steam blowing, prior to start-up of a new unit, is to remove any foreign material in the superheater and steam piping after the erection completion. Considerable …

Read More »Steam Boiler Alkali Boil out Procedure

Boiler Alkali boil out is carried out to remove material such as lubricants, oil, and rust. During the manufacturing of seamless steel tubes, mill scales are bound to be formed, and some of these can remain inside. During fabrication and erection of the pressure parts, some amount of oil and …

Read More »Boiler gas tightness test procedure

We will discuss important steps involved in Boiler gas tightness test procedure. -Close all the dampers in the grate hopper of the boiler. -Run the FD fan and open all the dampers excluding the dampers in the grate hopper. Keep air pressure and running time as approved by design. Detect …

Read More »Boiler Refractory Dry Out Procedure

Boiler refractory dry out is a critical process to ensure the longevity and optimal performance of the refractory lining within a boiler. It involves a controlled heating schedule to remove moisture, cure the refractory, and allow it to achieve its designed strength and integrity. The article provides a good overview …

Read More » Boilersinfo Boiler and Mechanical Power Digital Library

Boilersinfo Boiler and Mechanical Power Digital Library