Boiler design is the process of designing boilers used for various purposes. The main function of a boiler is to heat water for steam generation. Steam produced can be used for a variety of purposes including space heating, sterilization, drying, humidification, and power generation. The temperature or condition of steam required for these applications is different, so how to design a boiler varies accordingly.

The Thermal Design of a Boiler

The Thermal design of a water tube boiler involves determining the heat transfer characteristics of the various components of the boiler and calculating the heat input and output required to achieve the desired steam generation rate. This involves analyzing the heat transfer characteristics of the furnace, superheater, economizer, and other components, as well as considering factors such as fuel type, operating pressure and temperature, and steam demand.

Overall, the thermal design of a water tube boiler requires a comprehensive understanding of heat transfer, combustion, fluid mechanics, and control systems. It is a complex process that requires careful consideration of all factors involved to ensure the safe and efficient operation of the boiler.

The Mechanical Design of a boiler

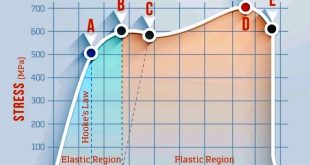

of a water tube boiler involves designing the various components to withstand the internal and external loads and stresses that they will be subjected to during operation. This includes designing the tubes and tube sheets to withstand the pressure and temperature of the steam and water, as well as designing the structural supports and connecting hardware to support the weight of the boiler and withstand the forces generated during operation.

The process of designing a water tube boiler involves a combination of engineering calculations and analysis, as well as the use of specialized software tools and industry codes and standards. It is a complex and detailed process that requires a thorough understanding of thermodynamics, heat transfer, and mechanical engineering principles.

Accessories and mountings are devices, which form an integral part of a boiler but are not mounted on it. They include economizers, superheaters, feed pumps, and air pre-heaters. Accessories help in controlling and running the boiler efficiently. Certain common mountings include:

- Feed check valve – regulates the flow of water into the boiler and prevents the backflow of water in case of failure of the feed pump.

- Steam stop valve – regulates the flow of steam that is produced in the boiler to the steam pipe, and may also be used to stop the supply of steam from the boiler

- Fusible plug – placed at the lowest level of water and above the combustion chamber, its function is to extinguish the fire as soon as the water level in the shell of the boiler falls below a certain marked level.

- Blow-off cock – removes water from the shell at regular intervals to remove the various impurities that may be settled at the bottom of the shell.

- Safety valves – automatically prevent the steam pressure from exceeding safe levels

- Water-level indicators – indicate the level of water in the shell

What are the Basic steps in Boiler Design

The basic steps involved in designing a boiler are as follows:

- Determination of steam requirements: The first step in designing a boiler is to determine the amount of steam that will be required for the intended application. This will involve determining the pressure and temperature requirements of the steam, as well as the rate at which it will be needed.

- Selection of fuel: The choice of fuel will depend on a number of factors, including availability, cost, and environmental considerations. Common fuels for boilers include natural gas, oil, coal, and biomass.

- Calculation of heat transfer requirements: Once the steam requirements and fuel have been determined, the next step is to calculate the heat transfer requirements. This will involve calculating the amount of heat that will be required to raise the temperature of the water to boiling point, as well as the amount of heat that will be required to convert the water to steam.

- Sizing of boiler components: The sizing of boiler components, such as the furnace, tubes, and heat exchanger, will depend on the calculated heat transfer requirements. The dimensions of these components will need to be chosen to ensure that they can handle the required amount of heat transfer.

- Selection of boiler type: There are several types of boilers available, including fire-tube, water-tube, and electric boilers. The choice of boiler type will depend on factors such as the fuel being used, the steam requirements, and the intended application.

- Design of control systems: The final step in designing a boiler is to design the control systems that will be used to regulate the temperature, pressure, and flow of steam and water. These control systems will need to be designed to ensure the safe and efficient operation of the boiler.

Based on the above-mentioned definition of a boiler and defining the accessories and mountings of a boiler system, we can now discuss the physical and mechanical principles that a boiler compiles with during its functioning process.

Normally a boiler is designed to suit the user’s requirements. Therefore, the boiler design starts with the basic specifications stated by the user or customer.

The customer’s preliminary specifications usually contain the following items:

- Steam penetration – Maximum Continuous Rating (MCR)

- Steam pressure

- Steam temperature

- Load range (Boiler turndown)

- Fuel

The basic boiler design often begins with just these four or five parameters, and continues to diversify into finer details along the way, as further details of operation; site-specific requirements get discussed and determined. For an optimum design of a boiler system, it is recommended to take the following steps to fulfill a reliable and durable design of a boiler.

Here are the basic steps in how to design a boiler:

-

- Calculation of boiler Heat Duty

- Using desired steam parameters, calculate the enthalpy of steam to be generated

- Multiplying enthalpy with the rated steam generation, obtain the total heat value of steam at rated steaming (boiler heat duty)

- Boiler heat duty is expressed as MKCal/hr or MW or HP

- Calculation of Burner Heat Duty and fuel firing rate

actually, Burner heat duty is defined by the rated steam enthalpy at MCR divided by boiler efficiency- With an assumed boiler efficiency number, calculate the heat duty of the burner

- Knowing the NCV of fuel, calculate the MCR rate fuel firing at MCR

- Fixing furnace geometry

- Select the burner(s) suitable for the calculated fuel firing rate

- From burner size and flame clearance requirements, configure front wall geometry

- Calculation of furnace volume required

- Using guideline/ limit for VHRR (Volumetric Heat Release Rate)

- Calculation of required FEGT

- FEGT (Furnace Exit Gas Temperature) has a direct effect on heat available to the superheater

- The flue gas temperature entering the superheater is determined from the desired final steam temperature, i.e. the degree of superheat

- Calculation of required EPRS

- EPRS (Effective Projected Radiant Surface) is the radiant surface available to pick up the heat from flue gas

- This is calculated from the required value of FEGT

- EPRS is the surface of furnace tubes directly exposed to radiation, plus the surface formed by membrane strips/ fins

- This determines the number of tubes required in the furnace section

- Freezing furnace configuration

- With EPRS, Burner flame clearance requirement, and front wall dimensions. Calculate furnace depth and configure furnace.

- Calculation of convection bank surface

- This is done by using FEGT and Heat absorption required for steam generation, then it is necessary to calculate the heat transfer surface required in the boiler bank and subsequently, use this to calculate the number of tubes required in generating bank

- Selecting Steam Drum

Let me explain more about the Steam drum size, which is governed by the following factors:- Boiler steaming capacity at MCR

- Circulation ratio

- Expected load fluctuations

- Steam-water separation equipment (in the steam drum)

- Number of generating bank tubes entering the steam drum (for ligament efficiency)

- Calculating economizer surface

- Calculate the minimum flue gas temperature required to avoid dew point corrosion

- This is grossly affected the sulfur content in the fuel

- The higher the sulfur content, the higher is the required flue gas temperature at the stack

- From the economizer inlet flue gas temperature and the desired stack temperature, calculate the economizer surface

- Calculating FD/ ID fan duty

- From MCR fuel firing rate and excess air requirement of the burner, calculate the air flow rate required

- From the burner data sheet and air duct configuration, calculate the FD fan head

- From the flue gas side pressure drop, gas temperature, and total gas weight, calculate ID fan duty and size the fan

- Calculation of stack height

- Stack height is calculated based on the following criteria:

- Weight SO2 emitted from the stack at 6MCR operation

- Natural draft considered as available while calculating ID fan duty

- The regulation governing the dispersal of pollutants (population around the boiler plant)

- Stack height is calculated based on the following criteria:

- Workout boiler mountings and fittings

- Decide the numbers, location, and capacities of safety relief values on steam and water circuits (follow applicable regulations)

- Work out the sizing of direct water level gauges (follow applicable regulations)

- From MCR fuel firing rate and excess air requirement of the burner calculate the air flow rate required

- Calculate expected thermal expansions at various locations and develop a thermal expansion drawing

- Carrying out stress analysis calculations for the configured boiler

- Stress analysis calculation brings out the stress pattern for each pressure part

- It is mandatory to prepare a complete stress analysis calculation under rated temperature and pressure and obtain approval from statutory authority, before commencing manufacturing/ assembly of the boiler

- Developing a safety protection system (PLC) and control system (DCS)for the configured boiler

- Follow NFPA-85 guidelines for BMS Burner management system

- Follow designer standards for control loops

- Calculation of boiler Heat Duty

Modern water tube boiler design benefits

What are the benefits of modern boiler design? To answer this important question we must know that modern boiler design offers several benefits. In the past, improper design of boilers has caused explosions, which led to the loss of life and property. Modern designs attempt to avoid such mishaps. Further, mathematical modeling can determine how much space a boiler will need and the type of materials to be used. When the design specifications of a boiler are determined, design engineers can estimate a cost and time schedule for the construction.

How to design a boiler? First, we must know that it may be based upon:

- Production of a maximum quantity of steam with minimal fuel consumption

- Economic feasibility of installation

- Minimal operator attention is required during the operation

- Capability for quick starting

- Conformity to safety regulations

- Quality of raw water: how hard or soft the water is will determine the material of the boiler.

- Heat source – the fuel to be burned and it’s ash properties or the process material from which the heat is to be recovered.

- Capacity/steam output required, usually measured in tonnes per hour or kg/s.

- Steam condition – pressure, temperature, etc.

- Safety considerations

- Mechanical constraints

- Cost restrictions

- Monetary cost

- The tensile strength of the material must be considered while using any joining processes.

- Simple Vertical Boiler Working, Fire Tube Boiler, Package Boiler,

- Boiler books, Water tube Boiler

Boilersinfo Boiler and Mechanical Power Digital Library

Boilersinfo Boiler and Mechanical Power Digital Library