A vertical boiler is a type of steam boiler that is designed with a vertical cylinder shape. Vertical boilers are often used in small- to medium-sized facilities, such as schools, hospitals, and small industrial plants, where space is at a premium.

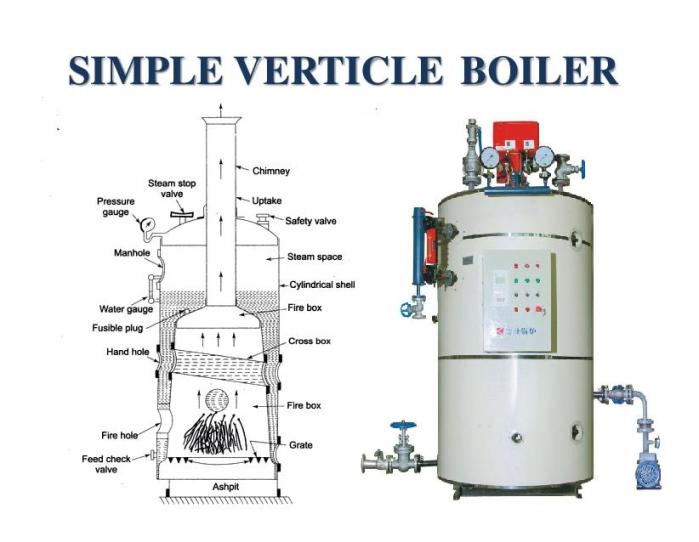

This is the simplest type of fire tube boiler. A simple vertical boiler produces low Pressure and a small quantity of steam. It occupies very less space so it is used where limited space is available. We discuss simple vertical boiler working design and its Parts. A simple vertical boiler diagram is shown.

It consists of a cylindrical shell surrounded by a vertical cylindrical box named called a firebox. This is slightly tapered towards the top of the shell to allow the ready passage of the steam to the surface. At the bottom of the firebox, is a grate. The firebox is fitted with two or more inclined cross tubes. These tubes are used to increase the heating surface of a simple vertical boiler and also increase water circulation. At the top of the firebox, there is a stack (Produce Natural Draught). Hand holes are provided at the end of cross tubes to clean them. A manhole is also available at the top of the shell for a man to enter in the boiler for cleaning or maintenance. A mud hole is provided at the bottom of the shell to remove the mud that settles down. The space between the boiler shell and the firebox is filled with water to be heated. A tubular gauge glass is also provided to see the water level inside the boiler. A pressure gauge, safety valve, air vent valve, and steam supply valves are also installed there at the top of the crown plate.

Simple vertical boiler working

The fuel is fed into the grate through the fire hole. when fuel is burnt, the ashpit is used to collect the ash from the burning fuel which is located at the bottom of the grate. The boiler dia is normally 3 feet and 9 inches to 5 feet and its height is 9 feet .each cross tube has a dia of 9 inches. The boiler heating surface is 80 feet square and its grate area 8.4 feet square. The boiler pressure is 100 PSI. The combustion gas flows from the furnace and passes around the tubes. These gasses escape to the atmosphere through the chimney. Due to natural circulation hot water moves from the lower end to the higher end. The supply of steam is then regulated through a stop valve.

There are several types of simple vertical boilers that are commonly used in small- to medium-sized facilities, including the following:

Fire-tube simple vertical boilers:

These boilers are designed with a series of tubes through which hot gases from a furnace pass and heat the water surrounding the tubes. The hot gases rise through the tubes, transferring heat to the water, and the resulting steam is used to heat a space or power an industrial process.

Fire-tube vertical boilers are a type of boiler that utilizes a series of tubes to transfer heat from hot gases generated by a furnace to the water surrounding the tubes. The tubes are arranged vertically, and the hot gases rise through the tubes, transferring heat to the water and generating steam. The resulting steam is used for various industrial processes or to heat a space.

These boilers are commonly used in small-scale applications and are relatively simple in design and operation. They are typically used in stationary applications, such as in buildings, and are not suitable for mobile or portable applications.

Fire-tube vertical boilers are often used in industrial processes where a moderate amount of steam is required, such as in laundries, dry cleaners, and small-scale manufacturing facilities. They are also used in heating applications, such as in small apartment buildings or in areas with limited access to natural gas or other fuel sources.

Electric simple vertical boilers:

These boilers use electricity to heat water or generate steam and do not require a fuel source such as coal, oil, or gas. They are an alternative to gas- or oil-fired boilers and are often used in facilities where access to a fuel source is limited or where there are concerns about emissions.

Electric vertical boilers are a type of boiler that uses electricity to heat water or generate steam. Unlike traditional boilers that require a fuel source, such as coal, oil, or gas, electric boilers use electricity to heat water and generate steam. They are often used as an alternative to gas or oil-fired boilers and are particularly useful in facilities where access to a fuel source is limited or where there are concerns about emissions.

Electric vertical boilers come in a range of sizes and are typically used in small-scale applications, such as in homes, small commercial buildings, and laboratories. They are often used in heating applications, such as for radiant floor heating or in areas where space heating is required.

Electric vertical boilers are typically more efficient than traditional boilers, as they do not suffer from energy losses associated with the combustion of fuel. They are also relatively simple in design and operation, requiring minimal maintenance and supervision. However, their use is limited by the availability of electricity and the cost of electricity in some areas.

Wood-fired simple vertical boilers:

These boilers use wood as a fuel source and are often used in rural or remote areas where access to other fuel sources is limited. Wood-fired boilers are relatively simple in design and operation and are often used in small-scale heating and power generation applications.

Wood-fired vertical boilers are a type of boiler that uses wood as a fuel source to generate heat and produce steam. They are often used in rural or remote areas where access to other fuel sources is limited. Wood-fired boilers are relatively simple in design and operation, and they can be an effective and sustainable heating solution in the right circumstances.

Wood-fired vertical boilers come in a range of sizes, from small residential units to large industrial-scale systems. They typically have a firebox where the wood is burned and a series of tubes or pipes that carry the hot gases generated by the fire through the water or steam. The hot gases transfer heat to the water, generating steam that can be used for various industrial processes or to heat a space.

Wood-fired vertical boilers can be a sustainable heating solution, as wood is a renewable fuel source. However, they require a steady supply of dry, seasoned wood, and proper handling and storage of the fuel are critical to ensure efficient operation. Wood-fired boilers can also generate emissions, such as particulate matter, and their use may be subject to local air quality regulations.

Waste heat recovery vertical boilers:

These boilers are designed to recover and utilize the waste heat from industrial processes or power generation. They are often used in conjunction with other types of boilers or energy-producing equipment.

Waste heat recovery vertical boilers are a type of boiler that recovers and utilizes waste heat generated from industrial processes or power generation to produce steam or hot water. These boilers capture heat that would otherwise be lost and convert it into usable energy, making them an efficient and sustainable heating solution.

Waste heat recovery vertical boilers work by transferring heat from hot exhaust gases generated by an industrial process or power generation equipment through a series of tubes or pipes to water. The resulting steam or hot water can then be used for various heating or industrial processes.

These boilers are often used in conjunction with other types of boilers or energy-producing equipment, such as gas turbines or diesel generators. They can be used to supplement the primary heat source or to provide additional steam or hot water for industrial processes.

Waste heat recovery vertical boilers are commonly used in industries such as cement, steel, paper, and chemical production, where high-temperature processes generate large amounts of waste heat. They offer an efficient way to reduce energy consumption and operating costs, while also reducing greenhouse gas emissions and improving overall sustainability.

Also, Read the Package type Boiler

Boilersinfo Boiler and Mechanical Power Digital Library

Boilersinfo Boiler and Mechanical Power Digital Library