Introduction

Welding is a fundamental skill in metalworking, used to join metals in various industries, including construction, automotive, manufacturing, and artistic projects. This article explores the basics of welding, essential safety measures, necessary tools, and various welding and cutting processes. Additionally, we will discuss different welding projects that can enhance both skills and creativity.

Introduction to Welding

Welding is a fabrication process that involves joining metals by applying heat, pressure, or both. It is widely used in industrial applications and DIY projects, allowing the creation of strong and durable structures. The primary welding techniques include arc welding, gas welding, and resistance welding, each serving specific purposes based on material and application requirements.

Safety

Safety is the most crucial aspect of welding. Welders must wear appropriate protective gear, including:

- Welding helmets with proper shading

- Fire-resistant gloves and clothing

- Safety glasses

- Welding and cutting safety

- Respirators or fume extractors for ventilation Additionally, the workspace should be free of flammable materials, and proper fire safety equipment should be on hand.

Setting Up Shop

A well-organized welding shop enhances efficiency and safety. It should have proper ventilation, fire-resistant flooring, and designated areas for different tasks. Essential shop considerations include workbench placement, storage for materials, and access to power sources.

Shop Tools

Essential tools in a welding shop include:

- Welding machines

- Angle grinders

- Clamps and vises

- Wire brushes

- Chipping hammers

- Measuring tools such as calipers and squares These tools assist in preparing, executing, and finishing welding projects efficiently.

Metal Basics

Understanding metal types is crucial for welding. Common metals used include:

- Mild steel

- Stainless steel

- Aluminum

- Cast iron Each metal requires specific welding techniques and settings for optimal results.

Welding & Cutting Processes

Several welding and cutting processes exist, each suited for different applications.

Oxyacetylene Welding

Oxyacetylene welding uses a mixture of oxygen and acetylene gas to produce a high-temperature flame. It is commonly used for welding thin metals and performing repairs.

Electricity for Welding

Electricity is essential in most modern welding processes. It provides the heat necessary to melt and fuse metals, requiring proper voltage and amperage settings for various techniques.

Shielded Metal Arc Welding (SMAW)

Also known as stick welding, SMAW uses an electrode coated in flux to produce the weld. It is versatile and suitable for outdoor and industrial applications.

Gas Metal Arc Welding (GMAW)

Commonly known as MIG (Metal Inert Gas) welding, GMAW utilizes a continuous wire electrode fed through a welding gun with shielding gas to prevent contamination.

Gas Tungsten Arc Welding (GTAW)

Also known as TIG (Tungsten Inert Gas) welding, GTAW provides precise, high-quality welds using a non-consumable tungsten electrode and a shielding gas such as argon.

Plasma Cutting

Plasma cutting uses a jet of ionized gas to cut through electrically conductive materials with precision and speed.

Oxyacetylene Cutting

This method uses oxygen and acetylene to cut through metal by oxidizing it at high temperatures.

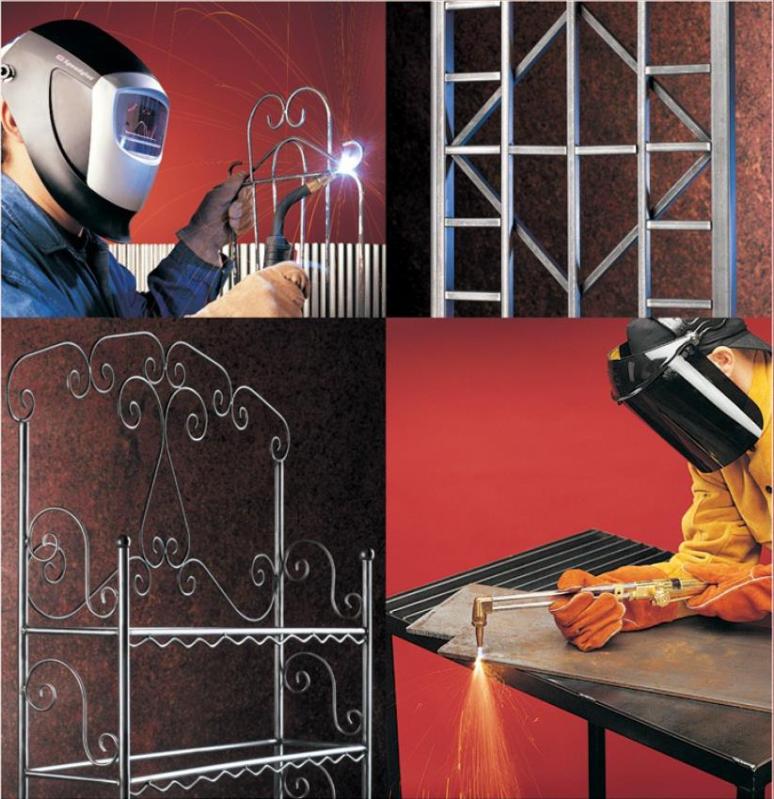

Welding Projects

Welding projects provide excellent opportunities to apply welding techniques and develop skills. These projects range from practical shop tools to artistic and functional furniture.

Shop Projects

- Rolling Welding Curtain: A mobile curtain protects workers from welding sparks and UV light.

- Welding Table: A sturdy, fire-resistant table provides a solid work surface.

- Welding Machine Cart: A cart for organizing and transporting welding machines and accessories.

- Cylinder Cart: A secure cart for transporting gas cylinders safely.

- Grinder Stand: A dedicated stand for angle grinders enhances workflow efficiency.

Lighting Projects

- Scroll Desk Lamp: A decorative, functional lamp incorporating intricate metal scrollwork.

- Three Post Floor Lamp: A stable, industrial-style floor lamp.

- Chandelier: A custom-designed metal chandelier for home or workshop lighting.

- Wall-mounted Candleholder: A metal-crafted holder for candles mounted on walls.

- Tree-shaped Candleholder: A tree-inspired artistic candleholder.

- Fireplace Candleholder: A sturdy candleholder designed for fireplaces.

Furniture Projects

Welding is widely used in furniture making, allowing for the creation of custom chairs, tables, and shelves. Metal furniture is durable, stylish, and can be designed in various styles to suit different environments.

Conclusion

Welding is a valuable skill that combines technical knowledge, precision, and creativity. Whether working on industrial applications or personal projects, mastering different welding techniques and safety protocols is essential. By exploring various welding and cutting processes, as well as engaging in diverse projects, welders can refine their craft and create high-quality metalwork.

Book

Welding Basics An Introduction to Practical & Ornamental Welding.

Boilersinfo Boiler and Mechanical Power Digital Library

Boilersinfo Boiler and Mechanical Power Digital Library