Boiler preservation is required when boiler is out of service or in shutdown condition for a long period to protect boilers internal surface from corrosion and atmospheric oxygen. There are two types of boiler preservation methods each of them is used in specific conditions. Wet preservation of boiler Dry preservation …

Read More »Boiler Feed Water Pump Working Principle and Operation

Today we will discuss about (BFWP) boiler feed water pump working principle and operation of a boiler feed water pump. The boiler feed pump function is to supply pressurized feed water to the boilers to maintain the water inventory at various operating loads. Boiler feed water pumps are commonly centrifugal pumps. …

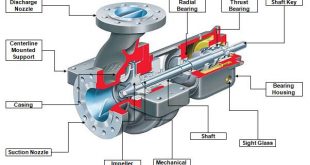

Read More »Centrifugal Pump Components

Centrifugal pump Components vary in design and construction from simple pumps with relatively few parts to extremely complicated pumps with hundreds of individual parts. Some of the most common components found in centrifugal pumps are wearing rings, stuffing boxes, packing, and lantern rings. Wearing Rings Centrifugal pumps contain rotating impellers …

Read More »Classification of Centrifugal Pump

Classification of Centrifugal Pump Centrifugal pumps are classified in several ways. Pumps may be classified: • in terms of energy conversions (volute type and diffuser vane ring type); • in terms of fluid flow through the pump (radial, mixed flow and axial flow); • as either single stage or multistage …

Read More »What are Centrifugal pumps?

Introduction to Centrifugal pumps Centrifugal pumps are the most common type of pumps found in industrial applications. Centrifugal pumps enjoy widespread application partly due to their ability to operate over a wide range of flow rates and pump heads. The centrifugal pump, as the name implies, uses centrifugal force to transfer …

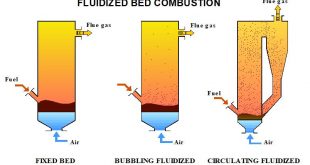

Read More »Fluidized Bed Combustion FBC Boiler

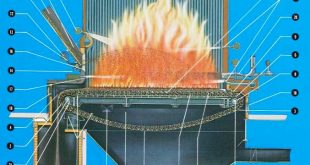

“ (FBC) Fluidized bed combustion is a combustion technology used to burn solid fuels in steam boilers.” In Fluidized Bed Combustion Boiler technology When air or gas is passed through an inert bed of solid particles such as sand supported on a fine mesh or grid, the air initially will seek a path of least resistance and pass …

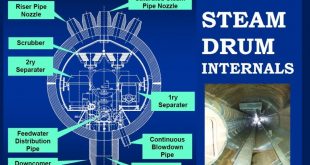

Read More »Boiler Steam drum internals and function

In the water tube boiler the upper drum (Boiler steam drum) provides for separation of steam from water. It also provides liquid holdup capacity (typically 10 to 60 seconds) to allow for a dynamic response to load changes without losing liquid in the downcomer and riser tubes. The size of the …

Read More »Boiler inspection Procedure requirement and Recommendations

Pressure vessels and Boiler Inspection are done to determine the amount of maintenance required to have equipment operate properly until the next turnaround. A comprehensive equipment history must be maintained that includes conditions found during inspection and testing, maintenance work done, changes made, and date of each. ASME Code Standards …

Read More »Boiler Design Basic Steps

Boiler design is the process of designing boilers used for various purposes. The main function of a boiler is to heat water for steam generation. Steam produced can be used for a variety of purposes including space heating, sterilization, drying, humidification, and power generation. The temperature or condition of steam required for …

Read More »Welding and cutting safety

Many hazards are associated with welding and cutting safety, but as in any other operations they can be controlled by appropriate preventive measures. Unless these measures are taken, the hazardous situations can easily give rise to personnel injury and/or material damage. Welding and cutting hazard examples are:- Electric shock Fumes …

Read More »Boiler Water Treatment Basic

Boiler Water Treatment is necessary to Produce quality steam on demand and depends on properly managed water treatment to control steam purity, deposits, and corrosion. There are two main types of boiler feed water treatment Internal boiler Water Treatment method and external boiler water treatment. A boiler is the sump …

Read More »Stoker Fired Boiler types of stokers

Stoker Fired Boiler are classified according to the method of feeding fuel to the furnace and by the type of grate. The main types of stokers are: Chain-grate or travelling-grate stoker Spreader stoker boiler Travelling Grate or chain grate Stoker Boiler In Travelling Grate boiler coal is fed at one …

Read More » Boilersinfo Boiler and Mechanical Power Digital Library

Boilersinfo Boiler and Mechanical Power Digital Library