Boilers play a central role in today’s energy and industrial landscape. From powering electrical grids across the globe to providing essential heat in process industries and commercial buildings, they are a cornerstone of modern infrastructure. Regardless of the fuel type—be it coal, natural gas, or oil—or the scale of operation, one truth remains constant: reliable and efficient boiler operation depends on precise control systems.

Boiler control system engineering is the discipline dedicated to designing and optimizing these systems. The purpose is simple yet vital: to fire a boiler safely, reliably, and efficiently. Achieving this requires a clear understanding of not only control logic but also accurate process measurement. As every experienced engineer knows, “If you can’t measure it, you can’t control it.”

The Foundation of Boiler Operation

Understanding boiler fundamentals is essential before diving into control systems. Boilers function by transferring heat to water, producing steam used for power generation or heating. Key components like steam drums, burners, and heat exchangers form the basis of this process. Whether it’s a small package boiler or a large utility boiler with multiple burners, the principles remain the same, though complexity scales up with capacity.

Essentials of Boiler Control

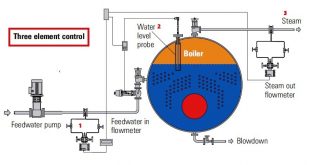

Effective boiler control ensures that critical variables like steam pressure, drum level, and combustion conditions remain stable and within design limits. Control systems range from simple single-loop configurations to complex, integrated distributed control systems (DCS) in large plants. Strategies like single-element, two-element, and three-element drum level control are deployed based on load variability and boiler size.

Managing Furnace Draft

Draft control maintains the pressure inside the furnace at safe levels. This is especially important in systems using Induced Draft (ID) and Forced Draft (FD) fans. Poor draft management can lead to operational instability or even safety risks like furnace implosion or uncontained flame conditions.

Feedwater Regulation

Maintaining the correct water level in the steam drum is critical to avoid overheating or flooding. Feedwater control systems ensure a constant balance between the water entering and steam exiting the boiler. Multivariable control schemes often integrate steam flow, feedwater flow, and drum level to achieve this delicate balance.

Considerations in Coal-Fired Systems

Coal-fired boilers add another layer of complexity. Solid fuel combustion requires control of coal feed rate, pulverizer operation, and distribution to multiple burners. Variations in coal quality also demand flexible control systems capable of adapting in real time.

Coordinating Fuel and Air

Fuel and air control is the backbone of efficient combustion. Maintaining the correct air-to-fuel ratio reduces unburned fuel and limits excess air, thereby improving efficiency and reducing emissions. Modern systems employ oxygen trim controls and flue gas analyzers to fine-tune this balance.

Regulating Steam Temperature

Controlling steam temperature is crucial for equipment longevity and process efficiency. Superheaters and desuperheaters are employed to manage steam properties, with feedback loops responding to changes in load and heat transfer conditions.

Safety through Burner Management

Burner Management Systems (BMS) ensure the safe startup, operation, and shutdown of boiler burners. These systems handle interlocks, purge sequences, ignition verification, and flame monitoring—automatically shutting down the system if unsafe conditions are detected.

Environmental Integration

Today’s boilers are not only judged by their output but also by their environmental impact. Control systems must interface with pollution control equipment such as Selective Catalytic Reduction (SCR) units, baghouses, and scrubbers. Precise control minimizes emissions and ensures compliance with environmental regulations.

The Role of Control Valves

Control valves serve as the final control element in most boiler systems. Proper sizing and selection of valves are critical for achieving desired flow characteristics, minimizing wear, and avoiding control loop instability. Engineers must consider valve coefficients, pressure drops, and actuator performance during the design phase.

Final Thoughts

Boiler control system engineering is a complex yet essential discipline for modern energy and industrial sectors. It combines process control, instrumentation, safety, and environmental management into one cohesive system. Professionals working with boilers—whether in utilities, refineries, manufacturing, or building systems—must grasp these core principles to ensure operational excellence.

By understanding how each component interacts and ensuring accurate measurement and control, engineers and technicians can create boiler systems that are not only safe and reliable but also environmentally responsible and economically efficient

Boilersinfo Boiler and Mechanical Power Digital Library

Boilersinfo Boiler and Mechanical Power Digital Library