The basic principles on which a boiler operates remains the same. Boilers also have different models, today we will talk about “fire tube boiler”.

What is a Fire tube boiler?

The universal type of steam boilers is the smoke tube or fire tube boiler where the heat and gases of combustion (from furnace) pass through tubes that are enclosed by water. While in water tube boilers, water passes through tubes. Mostly used boiler in small and medium industries with different fuels and steam pressure requirements.

Types of fire tube boiler

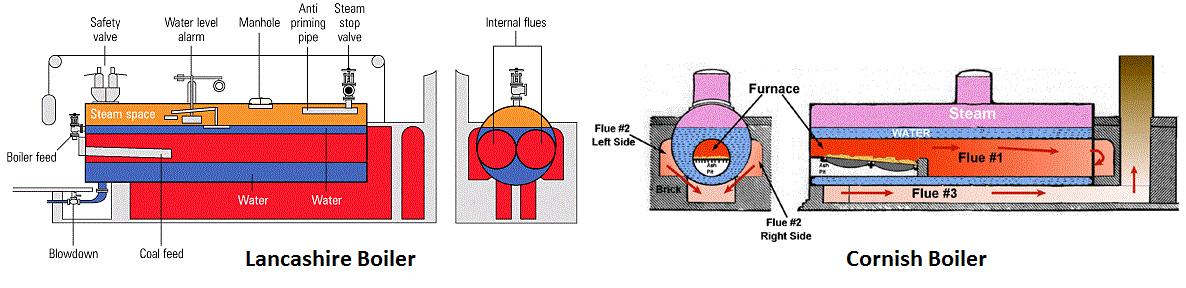

These steam boilers consist of many types and classifications. One is the Scotch Marine boiler, which consist of a cylindrical shell which length is lass as compare to its diameter having one or two combustion chambers and large no of fire tubes. The Lancashire has two and Cornish boiler has one flue and much more brickwork than the Scotch Marine. The locomotive boiler is another of the fire tube types. It is a portable model of the type used to drive power steam locomotives. The simple vertical boiler fire tube is no longer used in large installations but is still well-liked in heating homes. Fire tube boilers are design up to maximum pressure of 350 PSI.

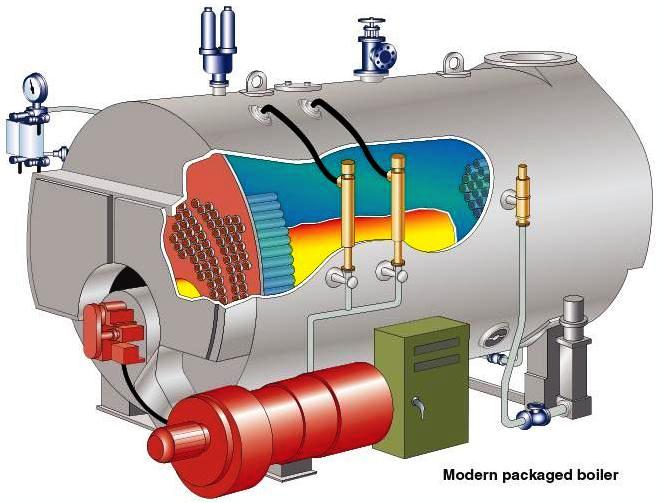

Package Boiler

Packaged boiler is the most common and efficient type of fire tube boiler used in industry to produce steam and hot water. This boiler delivers to site as a whole package factory assembled. The package boiler only requires electricity, water, steam and fuel connections and it is ready to produce steam. Package boiler has small combustion space and high heat release rate that is why it produces faster steam and result in high efficiency. Usually forced draught system is use in these types of boilers. The efficiency of these boilers is about 80%. Package boilers have limited range to produce maximum 45 ton per hr of steam. The parts of a typical duel fuel (gas & oil) fired Package type steam boiler is shown.

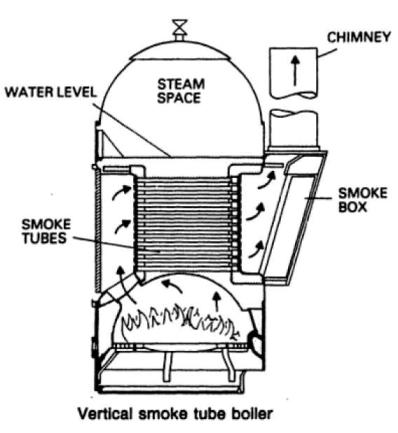

Working of simple vertical boiler

The most common type of simple vertical shell boiler direct fired gas water heat exchanger. Vertical boilers are compact and take up a small floor area. Vertical steam boilers have relatively low outputs. The cross tube is one of the smaller and simpler boilers. It has a vertical cylinder containing water, with a firebox at the bottom and a flue passing upwards through it to a chimney on top. Cross tubes of large diameter increase the surface through which heat from the hot gases transferred to the water. This type of design is thermally inefficient and mostly disappeared from the industry.

Cochran Boiler

The more efficient fire tube boiler has many tubes of small diameter passing through the water space of shell. Retarders are often fitted in these tubes, which increase the stay time of flue gases, this increasing the heating surface through which (fuels energy) heat is transfer to the water. Tubes are usually design horizontally which causses increase in the flue gas velocity. Design of furnace is also dished type, which provides larger radiant heating surface. All these factors increase the efficiency of this Cochran Boiler as compare to simple vertical boiler.

[bws_pdfprint]

Boilersinfo Boiler and Mechanical Power Digital Library

Boilersinfo Boiler and Mechanical Power Digital Library