Power Generation Handbook: Fundamentals of Low-Emission, High-Efficiency Power Plant Operation with a Focus on Steam Power Plants

In the evolving landscape of energy production, the demand for low-emission, high-efficiency power plants has never been greater. Power generation facilities worldwide are adopting innovative technologies and operational strategies to minimize environmental impact while maximizing performance. Among the cornerstones of this transformation are Steam Power Plants, which continue to play a pivotal role in the global energy mix, along with advancements in gas turbines, combined cycles, and electrical systems.

🚂 Steam Turbines and Their Auxiliaries

Steam turbines form the heart of traditional Steam Power Plants. They convert thermal energy from steam into mechanical energy, which in turn drives electric generators. The performance of steam turbines depends heavily on well-maintained auxiliaries such as feedwater systems, condensers, and heat exchangers. Precision in operation and design enhances efficiency and ensures reliable power generation.

Turbine Governing and Control Systems

The efficient operation of steam turbines requires sophisticated governing systems. These systems regulate turbine speed and load to match power demand while ensuring stability and safety. Modern digital control systems offer precise adjustments, improving response time and operational flexibility, which is crucial for balancing grid supply and demand.

Steam Chests, Valves, and Protective Mechanisms

Critical components like steam chests and control valves manage the flow and pressure of steam entering the turbine. Ensuring the integrity and proper function of these components helps prevent mechanical stress and energy losses. Protective devices such as overspeed trips, vibration monitors, and temperature sensors safeguard the turbines against failures and prolong equipment life.

📊 Instrumentation and 🛢️ Lubrication Systems

Accurate instrumentation is essential for monitoring and controlling turbine operations. Parameters such as temperature, pressure, vibration, and rotational speed are continuously measured to ensure safe and efficient performance. Lubrication systems play a key role in minimizing friction and wear in bearings and moving parts, directly impacting the longevity and efficiency of turbine machinery.

Gland Sealing Systems

Steam turbines require effective gland sealing systems to prevent steam leakage along the shaft where it exits the casing. These systems maintain pressure boundaries, minimize steam loss, and protect the environment, contributing to both efficiency and safety.

The Role of Gas Turbines in Modern Power Plants

In addition to Steam Power Plants, gas turbines have become central to modern power generation due to their high efficiency and fast startup capabilities. Components such as compressors, combustors, axial-flow turbines, and sophisticated materials ensure high-performance operation. Lubrication and fuel systems, along with advanced instrumentation and control systems, support the reliable operation of gas turbines.

Performance characteristics, operating conditions, and maintenance strategies for gas turbines directly influence their environmental footprint. New emission control methods and guidelines are helping operators meet stringent regulations while maintaining efficiency.

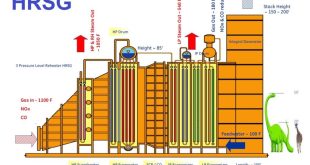

♻️Combined Cycles and Cogeneration: Efficiency Redefined

Combined cycle plants, which utilize both gas and Steam Power Plants, achieve remarkable efficiencies by capturing waste heat from gas turbines to generate additional power via steam turbines. This process significantly reduces fuel consumption and emissions.

Cogeneration, or combined heat and power (CHP), further enhances plant efficiency by utilizing waste heat for industrial processes or district heating. Selection of combined cycle or cogeneration configurations depends on economic, technical, and environmental considerations.

Electrical Systems and Machinery Principles

A key to high-efficiency power generation lies in the integration of robust electrical systems. Transformers, synchronous generators, and AC machines ensure the effective conversion of mechanical power into electrical energy and its delivery to the grid.

Understanding machinery principles, proper maintenance of transformer components, generator auxiliaries, excitation systems, and thorough inspection practices are essential to achieving operational excellence.

Conclusion & 📚⬇️

The transition toward low-emission, high-efficiency power plants is a multifaceted journey involving advanced steam and gas turbine technologies, combined cycles, cogeneration, and reliable electrical systems. Steam Power Plants continue to be indispensable in this evolution, especially when integrated with modern enhancements that boost efficiency and environmental performance.

By embracing innovation, optimizing operations, and committing to sustainability, the power generation industry can meet the growing global demand for clean, reliable energy.

Boilersinfo Boiler and Mechanical Power Digital Library

Boilersinfo Boiler and Mechanical Power Digital Library