Manual handling refers to any activity that requires us to use force to lift, push, pull, carry, or move in any other way a moving or non-moving object.

Each year a large percentage of Lost Time Injuries (that is injuries that resulted in one or more full shifts to be lost) were manual handling injuries. This percentage represents a significant amount of pain, suffering, and financial loss to the individuals who sustained these injuries.

No one gains when injuries and accidents occur both as individuals and also together as a company. We must all work together to identify problems and unsafe work practices and then take action to prevent accidents and injuries from occurring.

Hazards

Poor manual handling practices and accidents have the ability to cause both short and long-term health effects. Some injuries may be relatively minor and can heal quickly and effectively. Many other injuries particularly involving our backs may be serious and may take extended periods of time to heal, and in some cases may never heal completely.

Prevention must be the number one priority at all times.

Planning and Assessment of Risks

To prevent accidents from happening we need to be able to identify risks and situations that have the ability to cause harm to ourselves and those who work along with us.

Before any object is moved, the best and safest way of doing the job needs to be considered and established. This may simply be a case of thinking for a couple of seconds about the best way to lift or move an object, or alternatively in complex cases may involve a lot of thought, time, and effort going into determining the best way to get the job done by a number of personnel.

Risks associated with manual handling may include:

- Excessively heavy weights/loads

- Awkward loads or those that are difficult to grip and hold onto due to their size and shape.

- Repetitive movement is where a task is performed time and time again.

- Static loading of joints and muscles due to working in fixed or limited positions for extended periods of time.

- Poor or incorrect lifting techniques.

- Obstructions in the work area that may lead to slips, trips, and falls.

- Poor coordination of lifting efforts when lifting as a team.

- Eye Protection Safety

Planning is an important part of preventing manual handling-related injuries, we should always plan to do the job as safely and efficiently as possible. This planning is an important first step in safe work practices.

Safe Work Practices

When we are planning our work the following factors need to be considered in order to protect ourselves and maintain safety.

Does the item need to be lifted or moved?

By avoiding unnecessary movement of materials and equipment, we can eliminate the chance of being injured when trying to do so. A number of injuries have occurred here on site that should not have happened because the object should not have been moved in the first place.

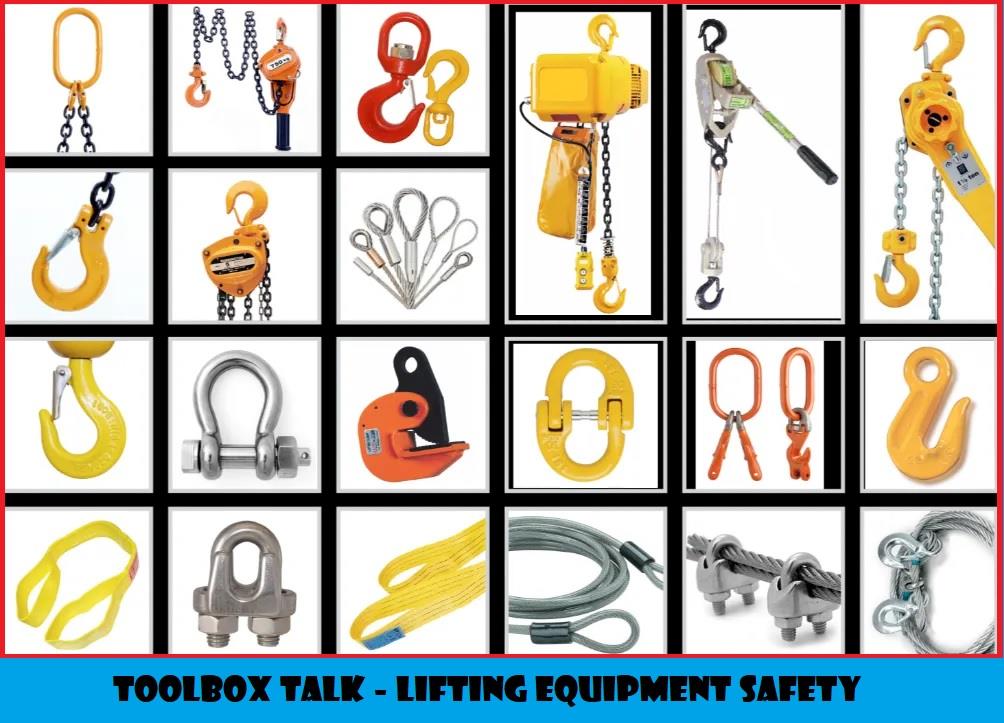

Can some form of mechanical lifting device be used?

Wherever possible, mechanical lifting aids should be used to lift and move objects in and around the workplace. By doing this, the lifting takes the strain and does most of the work, thus reducing the chance of us injuring ourselves.

Examples of mechanical lifting devices that can help make our jobs safer include:

- Forklifts and pallet lifters

- Cranes, hoists, and lifts

- Chain blocks and come along

- Jacks

- Trolleys

- 100 safety topics

Lifting as a team where it is not possible to mechanically lift or move an object, lifting together as a team can help reduce the risk of strains, sprains, and injury. It is important that team lifts are planned so everyone knows how they are going to lift the object and that everybody lifts together at the same time.

Loads where possible:

- Limit the size of loads and limit the weight of loads that are to be lifted.

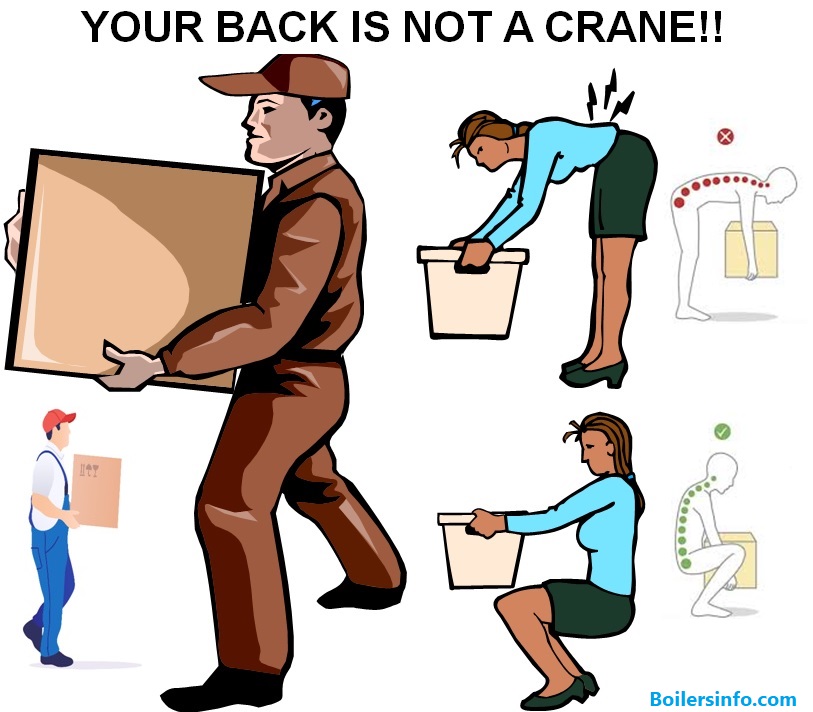

Lifting Technique

When lifting it is important to do it as safely as possible, this can be done by paying attention to the following points:

- Plan before you lift

- Ensure the route to be taken is clear and free of hazards

- Know the weight of the object before lifting

- Lifting equipment safety

- Get a firm grip on the object

- Lift using your leg muscles, not your back

- Hold loads as close to your body as possible.

The further away the load is held, the greater the strain on your body. - Avoid over-reaching.

- Hoisting and Rigging Safety Manual

- Keep your back straight and avoid twisting when carrying or lifting loads

- Know your limitations and don’t be afraid to ask for help if the load is too heavy.

- Avoid double handling where possible.

- Allow yourself time to recover in between lifts.

Reporting of Faults/Hazards

Any situations with the potential to cause harm need to be acted on to prevent them from causing accidents and injuries. Faults or defects that are identified in lifting equipment must be reported so action can be taken to fix the problem. Any faults or hazardous situations should be reported to your immediate supervisor for action.

Boilersinfo Boiler and Mechanical Power Digital Library

Boilersinfo Boiler and Mechanical Power Digital Library