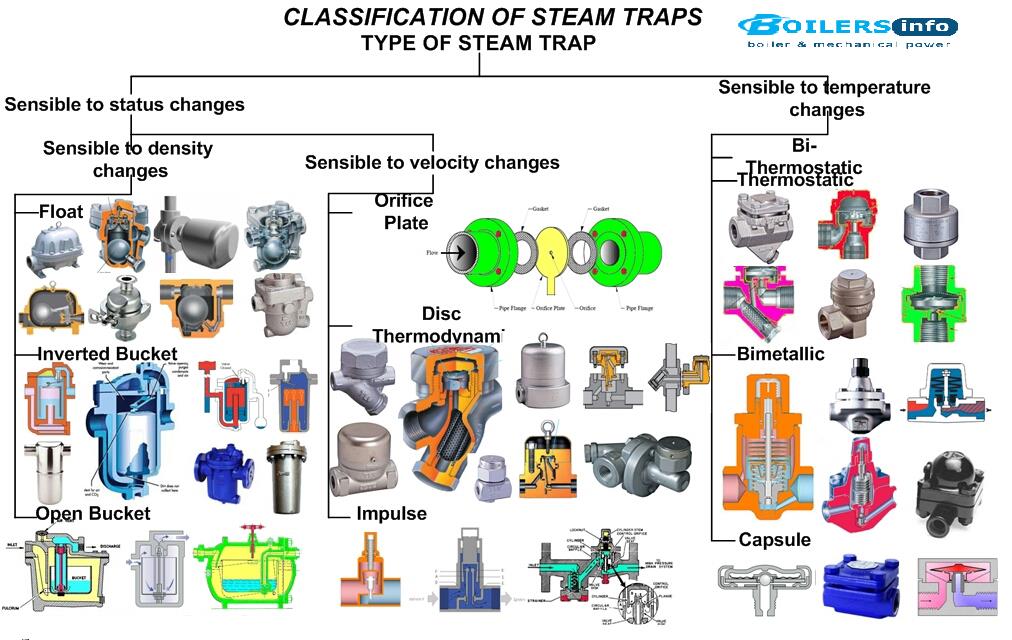

The function of steam trap:

Steam traps are installed in steam lines to drain condensate from the lines without allowing the escape of steam. There are many designs of steam traps for high and low-pressure use.

Steam Trap working

In general, a steam trap consists of a valve and a device or arrangement that causes the valve to open and close as necessary to drain the condensate from the piping without allowing the escape of steam. Steam traps are installed at low points in the system or machinery to be drained. Some types of steam traps that are used in the DOE department of energy facilities are described in this article.

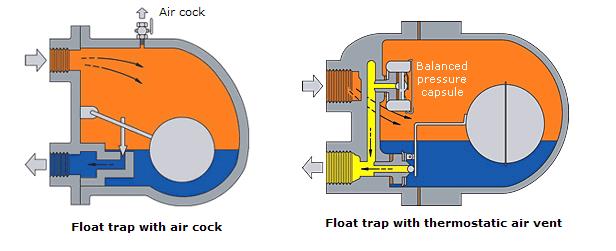

Ball Float Steam Trap

A ball float steam trap is illustrated in Figure 1. The valve of this trap is connected to the float in such a way that the valve opens when the float rises. When the trap is in operation, the steam and any water that may be mixed with it flow into the float chamber. The water, being heavier than the steam, falls to the bottom of the trap, causing the water level to rise. As the water level rises, it lifts the float; thus lifting the valve plug and opening the valve. The condensate drains out and the float moves down to a lower position, closing the valve before the condensate level gets low enough to allow steam to escape. The condensate that passes out of the trap is returned to the feed system.

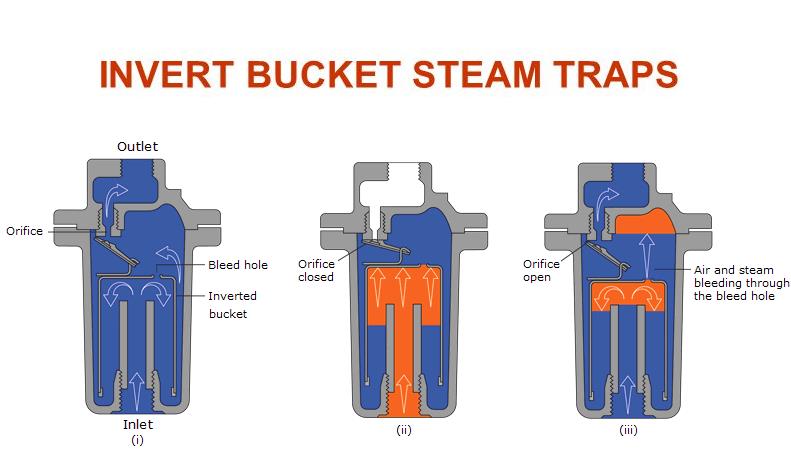

Bucket Steam Trap

A bucket steam trap is illustrated in the picture. As condensate enters the trap body, the bucket floats. The valve is connected to the bucket in such a way that the valve closes as the bucket rises. As condensate continues to flow into the trap body, the valve remains closed until the bucket is full. When the bucket is full, it sinks and thus opens the valve. The valve remains open until enough condensate has passed out to allow the bucket to float, and closing the valve. Inverted bucket steam trap is most common in this type of steam traps.

Thermostatic Steam Traps

There are several kinds of thermostatic steam traps in use. In general, these traps are more compact and have fewer moving parts than most mechanical steam traps.

Bellows-Type Steam Trap

A bellows-type steam trap is illustrated in Figure 3. The operation of this trap is controlled by the expansion of the vapor of a volatile liquid, which is enclosed in a bellows-type element. Steam enters the trap body and heats the volatile liquid in the sealed bellows, causing expansion of the bellows.

The valve is attached to the bellows in such a way that the valve closes when the bellows expand. The valve remains closed, trapping steam in the valve body. As the steam cools and condenses, the bellows cool and contract, thereby opening the valve and allowing the condensate to drain.

Impulse Steam Trap

Impulse steam traps pass steam and condensate through a strainer before entering the trap. A circular baffle keeps the entering steam and condensate from impinging on the cylinder or on the disk. The impulse type of steam trap is dependent on the principle that hot water under pressure tends to flash into steam when the pressure is reduced. The only moving part in the steam trap is the disk. A flange near the top of the disk acts as a piston. The working surface above the flange is larger than the working surface below the flange. A control orifice runs through the disk from top to bottom, which is considerably smaller at the top than at the bottom. The bottom part of the disk extends through and beyond the orifice in the seat. The upper part of the disk (including the flange) is inside a cylinder. The cylinder tapers inward, so the amount of clearance between the flange and the cylinder varies according to the position of the valve. When the valve is open, the clearance is greater than when the valve is closed.

Orifice-Type Steam Trap

DOE facilities may use continuous-flow steam traps of the orifice type in some constant-service steam systems, oil-heating steam systems, ventilation preheaters, and other systems or services in which condensate forms at a fairly constant rate. Orifice-type steam traps are not suitable for services in which the condensate formation is not continuous. Although there are several variations of the orifice-type steam trap, each has one thing in common; it contains no moving parts. One or more restricted passageways or orifices allow condensate to trickle through but do not allow steam to flow through. Some orifice-type steam traps have baffles in addition to orifices.

Steam Traps Summary

- A steam trap consists of a valve and a device or arrangement that causes the valve to open and close as necessary to drain the condensate from the lines without allowing the escape of steam. Steam traps are installed at low points in the system or machinery to be drained.

- The type of steam trap used depends primarily on its application. Types include ball float, bucket traps, thermostatic traps, bellows-type traps, impulse traps, and orifice type traps.

- Impulse steam traps pass steam and condensate through a strainer before entering the trap. A circular baffle keeps the entering steam and condensate from impinging on the cylinder or on the disk. The impulse type of steam trap is dependent on the fact that hot water under pressure tends to flash into steam when the pressure is reduced.

-

Water Tube Boiler Parts and Functions

-

Boiler Hydrostatic testing

Boilersinfo Boiler and Mechanical Power Digital Library

Boilersinfo Boiler and Mechanical Power Digital Library